[wpseo_breadcrumb]

Design features

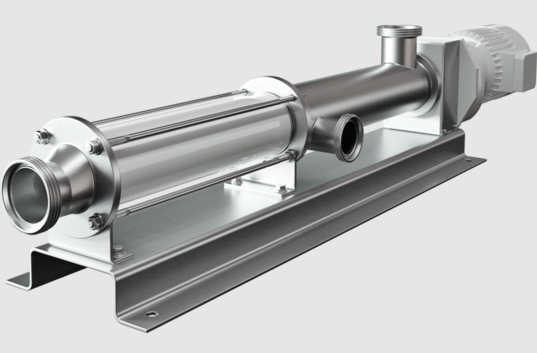

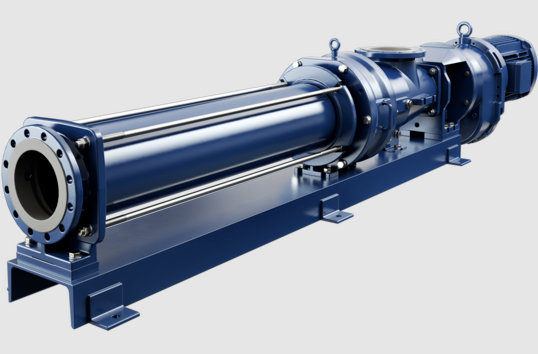

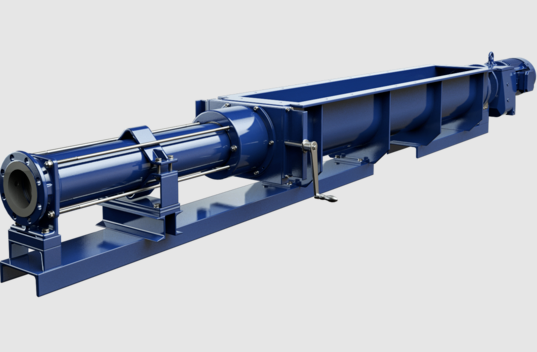

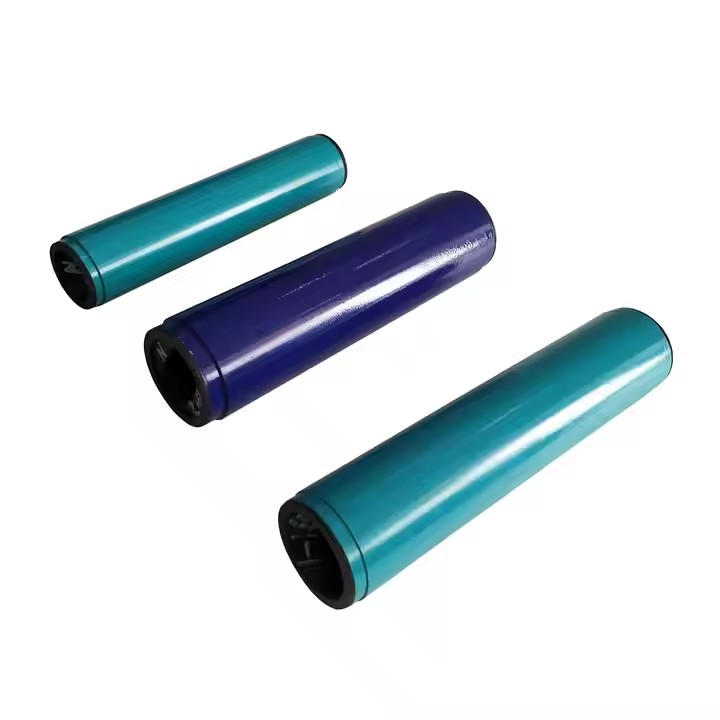

The seepex BN30-12T stator uses high-quality materials and advanced manufacturing processes. The stator of this pump has good wear and corrosion resistance and can withstand various harsh working environments. Its design takes into account the basic principles of fluid dynamics, making the fluid flow in the pump smoother, thereby reducing energy loss.

Performance features

The performance of the Seepex BN30-12T stator is mainly reflected in the following aspects:

- High efficiency: The design of the stator minimizes the friction when the fluid flows in the pump cavity, thereby achieving efficient transportation and reducing energy consumption.

- Strong adaptability: Its structure can adapt to the transportation of a variety of fluids, including high-viscosity fluids and fluids containing solid particles, so it demonstrates its advantages in many industrial applications.

- Low noise: Due to its sophisticated manufacturing process, the Seepex BN30-12T stator produces less noise during operation, which is particularly important in applications that require a quiet environment.

Maintenance and care

Regular maintenance and care are indispensable to ensure the long-term normal operation of the Seepex BN30-12T stator. Maintenance includes:

| Regular inspection: | Check the stator for wear regularly and replace damaged parts in time to prevent malfunctions. |

| Cleaning: | When handling fluids containing solids or viscous substances, cleaning the pump cavity can avoid clogging and damage. |

| Lubrication: | Proper lubrication can reduce friction and extend the life of pump components. |

Application areas

One of the great advantages of the Seepex BN30-12T stator is its wide range of applications, including:

- Food and beverage industry: In this industry, cleanliness and hygiene of the conveyed fluid are essential. The Seepex BN30-12T stator has become the preferred pump component for many food processing companies due to its material safety and easy-to-clean characteristics.

- Chemical industry: In the chemical industry, many chemicals are corrosive and highly viscous. The Seepex BN30-12T stator can effectively handle these fluids and ensure safe operation.

- Sewage treatment: In the sewage treatment process, various sewage and sludge must be handled. Pumps using the Seepex BN30-12T stator can efficiently convey these fluids and ensure stable operation of the equipment.

people also ask

Send Your Enquiry :