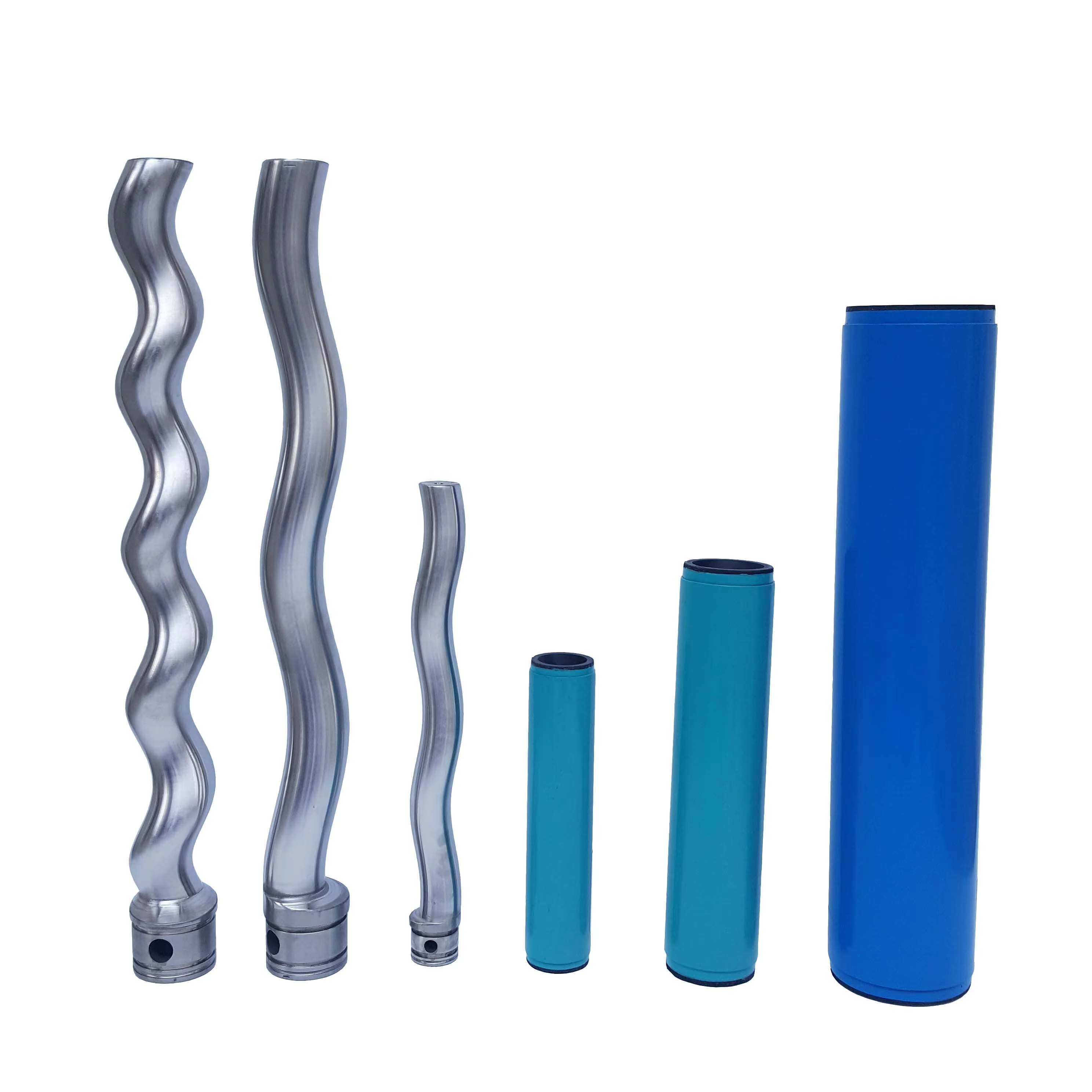

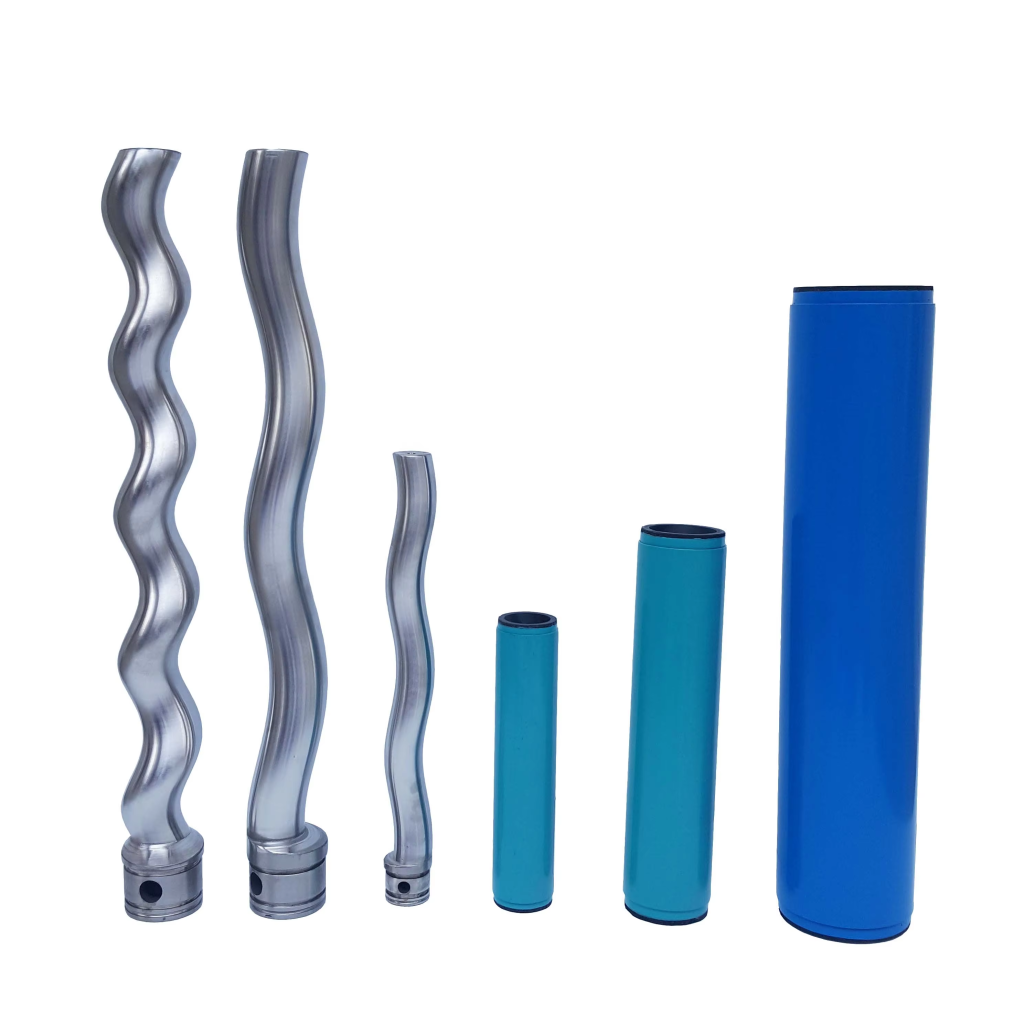

Structural features of Seepex BN100-6L Rotor

The Seepex BN100-6L rotor is made of high-strength materials to ensure stable operation under high pressure and high temperature. Its specially designed spiral shape allows the fluid to form a low-shear flow during the conveying process, avoiding damage to the fluid properties, and is particularly suitable for conveying fragile substances such as food, chemicals and biological materials.

The diameter and length of this rotor are precisely calculated to optimize the flow efficiency of the fluid. Compared with traditional pumps, this design of Seepex reduces the residence time of the liquid and improves the overall transmission efficiency. At the same time, the maintenance and replacement of the BN100-6L rotor are relatively simple, reducing operating and repair costs.

Working principle

The working principle of the seepex BN100-6L rotor is based on the rotational motion of the spiral rotor. When the rotor rotates, its spiral shape forms a series of closed cavities in the pump body, and the fluid is continuously sucked in and conveyed forward. Such a design can not only maintain the stable flow of fluids, but also effectively reduce the shear force of the fluid during the conveying process, which is particularly suitable for fragile or high-viscosity fluids.

Application areas

The wide application of the seepex BN100-6L rotor in the industry is mainly reflected in the following aspects:

Chemical industry: Reliable fluid handling is essential in chemical reactions and component delivery. The rotor can efficiently transport chemicals to ensure the safety and efficiency of the production process.

Food and beverage industry: In the food processing process, it is a common requirement to handle high-viscosity fluids (such as syrups, sauces, etc.). The seepex BN100-6L rotor can ensure the quality of the fluid with low shear force and meet food safety standards.

Wastewater treatment: Wastewater treatment facilities need to continuously and stably handle large amounts of liquids. The design of this rotor ensures effective operation under high load and high viscosity conditions, contributing to environmental protection.

Pharmaceutical industry: In pharmaceutical production, accurate fluid delivery and handling are very critical. The seepex BN100-6L rotor ensures that the agent will not be damaged during the conveying process and its active ingredients are maintained.

Performance and economic benefits

The high efficiency of pump systems using the seepex BN100-6L rotor enables companies to achieve significant energy savings in operation. At the same time, the rotor reduces maintenance frequency and downtime, thereby improving production efficiency. In many cases, companies have significantly reduced overall operating costs by optimizing the use of pumps.

Most customer feedback shows that pumps using this rotor show lower energy consumption and fewer failure rates during operation. This not only improves work efficiency, but also enhances the competitiveness of enterprises. This advantage is particularly important in the fierce global market competition.

people also ask

Send Your Enquiry :