[wpseo_breadcrumb]

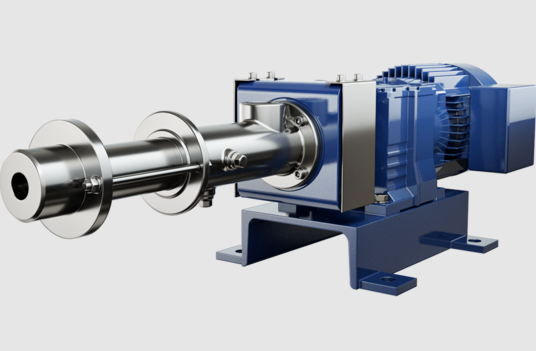

Advantages of seepex BN52-12L stator

seepex BN52-12L stator is widely favored in the industrial field due to the following advantages:

Excellent working performance

| Optimized flow channel design ensures a conveying efficiency of more than 90% |

| Wide compatibility, suitable for viscous, granular or easy-to-crystallize media |

| Excellent self-priming performance, greatly reducing the initial startup pressure of the system |

Excellent safety

| Well-designed thermal protection system, which can effectively monitor and prevent overheating |

| Rugged and durable structural design, able to withstand huge stress under high-pressure conditions |

| Complete certification system to ensure that the product meets various international safety standards |

Application scenarios of seepex BN52-12L stator

With excellent performance parameters, seepex BN52-12L stator is widely used in the following industrial fields:

- Chemical industry: conveying various chemical agents, pigments, acids and alkalis and other corrosive media.

- Food and beverage industry: conveying high-viscosity paste materials such as jam, honey, etc.

- Mining and metallurgy industry: conveying mud and ore pulp containing particulate impurities.

- Environmental protection field: used for sludge conveying in sewage treatment plants.

- Building materials industry: transporting cement slurry, mortar and other high-viscosity concrete-like materials.

- Papermaking industry: transporting fibrous materials such as paper pulp and filler pulp.

people also ask

Send Your Enquiry :