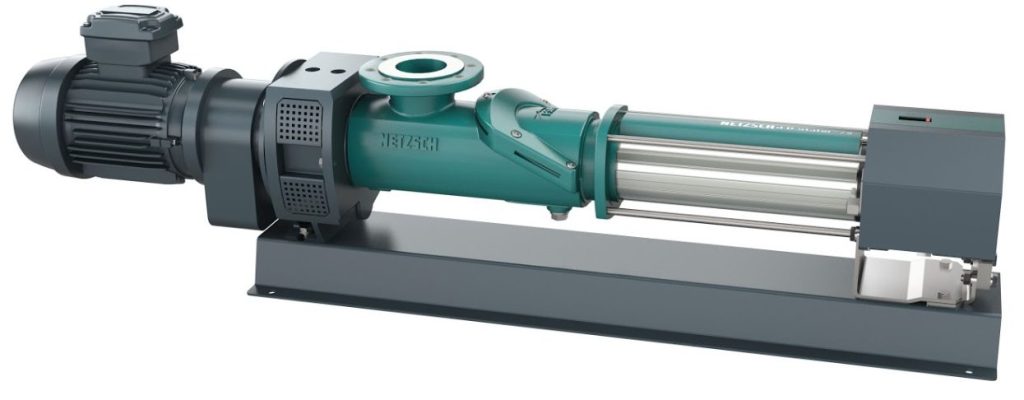

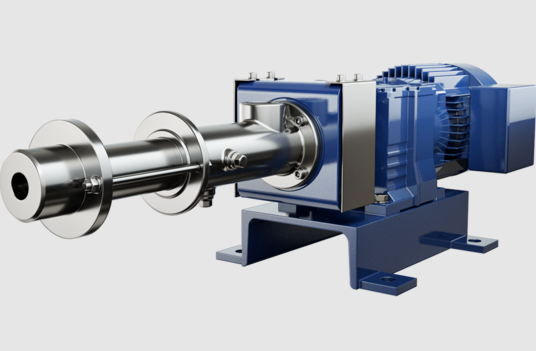

MOYNO G4 – 45 INLET DESIGN PUMPS

G4 – 45 INLET DESIGN The high-efficiency G4 progressing cavity pump’s 45°inlet lowers friction loss and provides for gentler handling of the product. People Also Ask

A Progressive Cavity Pump is a type of a progressive cavity pump which has a rotor rotating within a housing called a stator. The rotor is always metallic and the stator is made up of a rubber type of material. It looks somewhat like a screw thread – the fluid is between the cavities and the rotary motion of the rotor forces the fluid through from one end to the other.

Progressing Cavity Pumps are used when a product needs to be handled gently and are used in all sectors of industries to convey almost all types of media continuously, smoothly, with low pulsation and dosing in proportion to speed. They are used for dosing applications where accuracy is required (multi stage pumps) their range covers from the smallest dosing pumps with flow rates of a few ml to high-performance pumps that pump up to 1000 m³/h.

One of the main advantages of a progressive cavity pump is that it is easy to regulate the flow of product simply by regulating the speed of the pump.

Specific designs involve the rotor of the pump being made of a steel, coated with a smooth hard surface, normally chromium, with the body made of a molded elastomer inside a metal tube body. The elastomer core of the stator forms the required complex cavities. The rotor is held against the inside surface of the stator by angled link arms, bearings (immersed in the fluid) allowing it to roll around the inner surface (un-driven). Elastomer is used for the stator to simplify the creation of the complex internal shape, created by means of casting, which also improves the quality and longevity of the seals by progressively swelling due to absorption of water and/or other common constituents of pumped fluids. Elastomer/pumped fluid compatibility will thus need to be taken into account.

Two common designs of stator are the “equal-walled” and the “unequal-walled”. The latter, having greater elastomer wall thickness at the peaks allows larger-sized solids to pass through because of its increased ability to distort under pressure. The former have a constant elastomer wall thickness and therefore exceed in most other aspects such as pressure per stage, precision, heat transfer, wear, and weight. They are more expensive due to the complex shape of the outer tube.

G4 – 45 INLET DESIGN The high-efficiency G4 progressing cavity pump’s 45°inlet lowers friction loss and provides for gentler handling of the product. People Also Ask

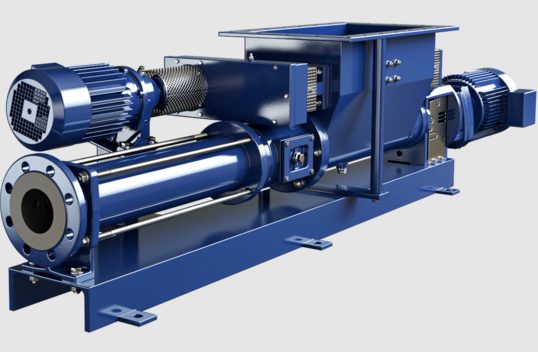

G2 – SINGLE AUGER FEED High-performance 2000 Pumps offer low maintenance, minimal downtime and long service life for low total cost of ownership. People Also Ask

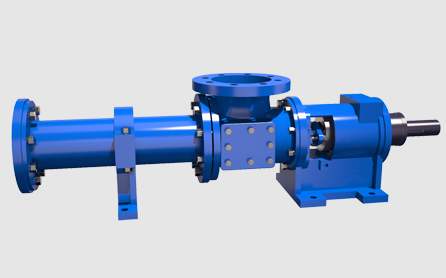

G1 – FLANGED DESIGN Versatile, high performance pump designed to handle a wide range of applications from shear-sensitive chemicals to difficult-to-process slurries and sludges. High-performance 2000 Pumps offer low maintenance, minimal downtime and long service life for low total cost of ownership. People Also Ask

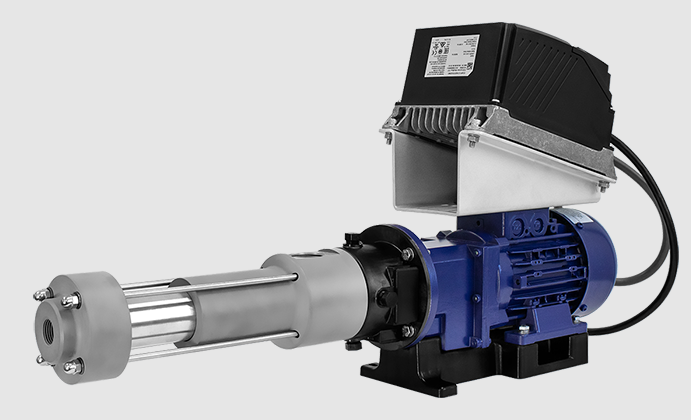

2000WA – CLOSE COUPLED DESIGN The 2000WA close coupled pump is specifically designed for lower pressure, lower flow applications that do not require the full features and benefits of the 2000G1 pump. The 2000WA features a close coupled design that has integral bearings that support the radial thrust loads that can be seen at the…

MXQ MM-Series Pumps MXQ MM-Series pumps are exact duplicates of the Moyno® 2000 series progressive cavity pumps. These pumps are manufactured to handle thrust and radial loads efficiently. Their high quality gear joints and materials of construction create a very robust, reliable option for your application. People Also Ask

MDR – Superior Process Control The MDR range design incorporates an external GA seal arrangement and engineered composite seal housing, lantern, and rotating unit. The only metallic part of the pump that is exposed to the conveyed product is the rotor. This design allows for broad chemical compatibility, increased performance, and decreased maintenance. The patented…

Open Hopper Cavity Pump Introduction Open Hopper Cavity Pump is a type of positive displacement pump that is designed to handle viscous and shear-sensitive materials. It has an open hopper or feeding area which allows for easy loading and unloading of the material being pumped. The pump’s unique design features a rotor that rotates inside…

The Description of NETZSCH PUMP Netzsch pump is a type of positive displacement pump that utilizes a progressive cavity design to handle difficult-to-pump fluids with high viscosity, abrasiveness, and shear sensitivity. This type of pump is designed with a helical rotor and stator that create a series of sealed cavities to move fluid through the…

The Description of Pump Hopper A pump hopper is an equipment used in the process of transferring materials from one location to another using a pump. It is designed to receive, store and feed material into the pump system efficiently and safely. The Application of Pump Hopper Pump hoppers are widely used in various industries…

DESIGNED WITH THREADED CONNECTIONS FOR GENERAL METERING APPLICATIONS MD Range progressive cavity pumps are used in virtually all industries for metering and dosing precise quantities. They are particularly good for minimal pulsation conveyance of thin to viscous fluids, as well as corrosive media containing solids. People Also Ask