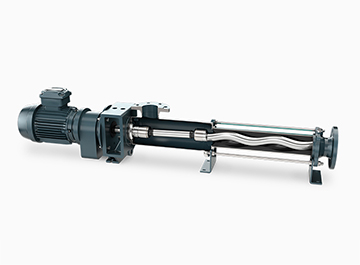

progressive cavity pump

The main working parts of a single screw pump are composed of a sleeve (stator) with a double-headed spiral cavity and a single-headed eccentric screw (rotor) meshed with it in the stator cavity. Since the medium of a single screw pump is pushed axially and evenly to flow, the internal flow velocity is low, the pressure is stable, and no eddy current or agitation is generated; it is suitable for conveying high viscosity, containing solid particles or high fiber, and requiring continuous and stable pressure.

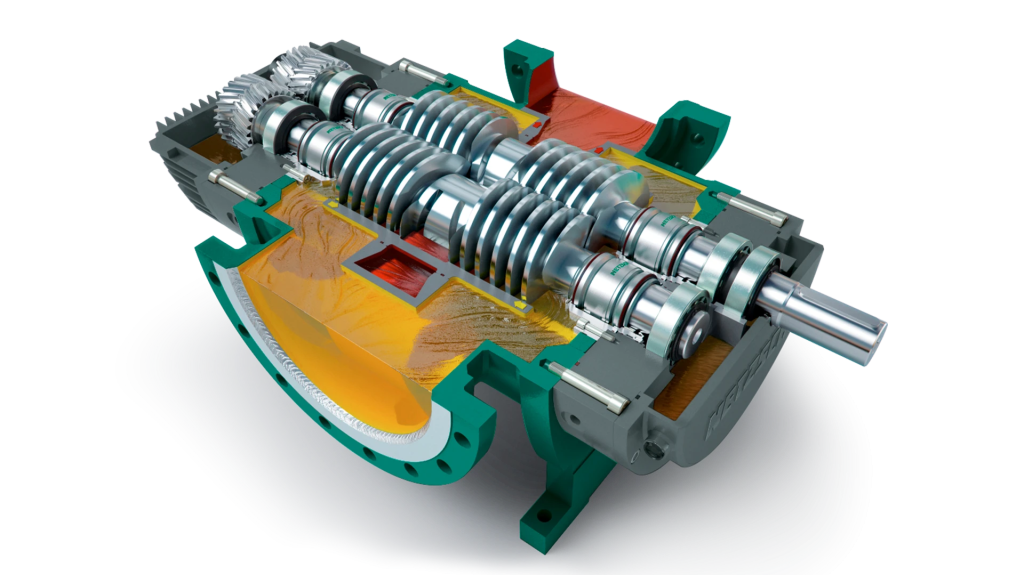

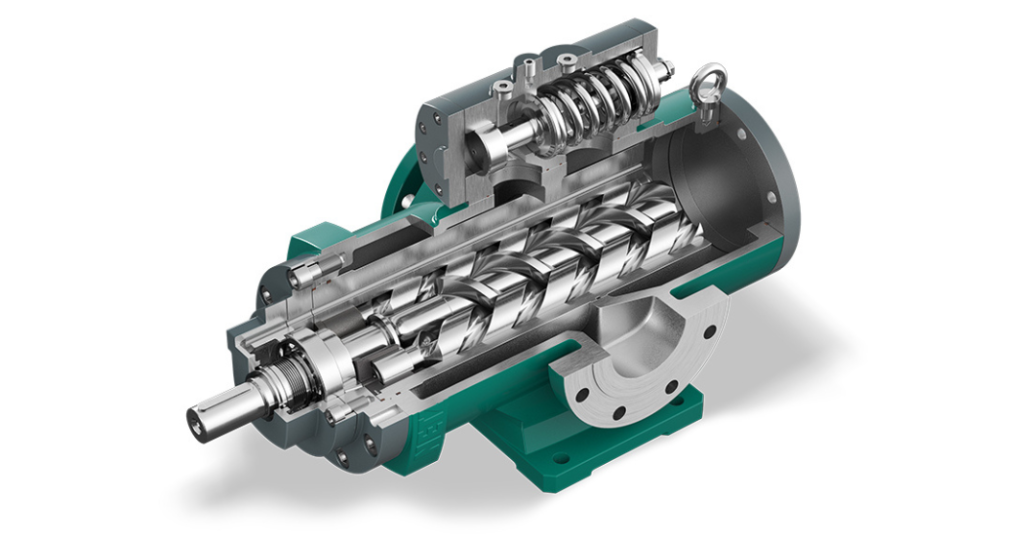

One of the twin-screw, three-screw, and five-screw pumps is an active screw, which is a right-handed convex screw, and the rest are driven screws, which are left-handed concave screws. When the screw rotates, the volume of the suction chamber increases and the pressure decreases. The liquid enters the suction chamber along the suction pipe under the action of the pressure difference between the inside and outside of the pump. As the screw rotates, the liquid in the sealed chamber moves continuously and evenly along the axial direction to the discharge chamber. As the volume of one end of the discharge chamber gradually decreases, the liquid is discharged.

Structural features

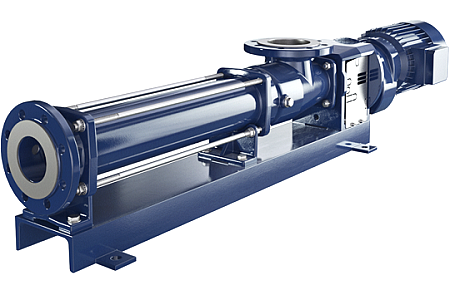

A twin-screw pump is an externally meshed screw pump, which uses two screws that mesh with each other and do not contact each other to pump liquid. The unique structure enables it to realize non-stirring, non-pulsating and stable conveying of various media; because the pump body structure ensures that the pumping liquid is always present in the working element of the pump as a sealing liquid, the twin-screw pump has a strong self-priming ability, and its special design also ensures that the pump has a high suction performance, that is, a very small NPSHr value.

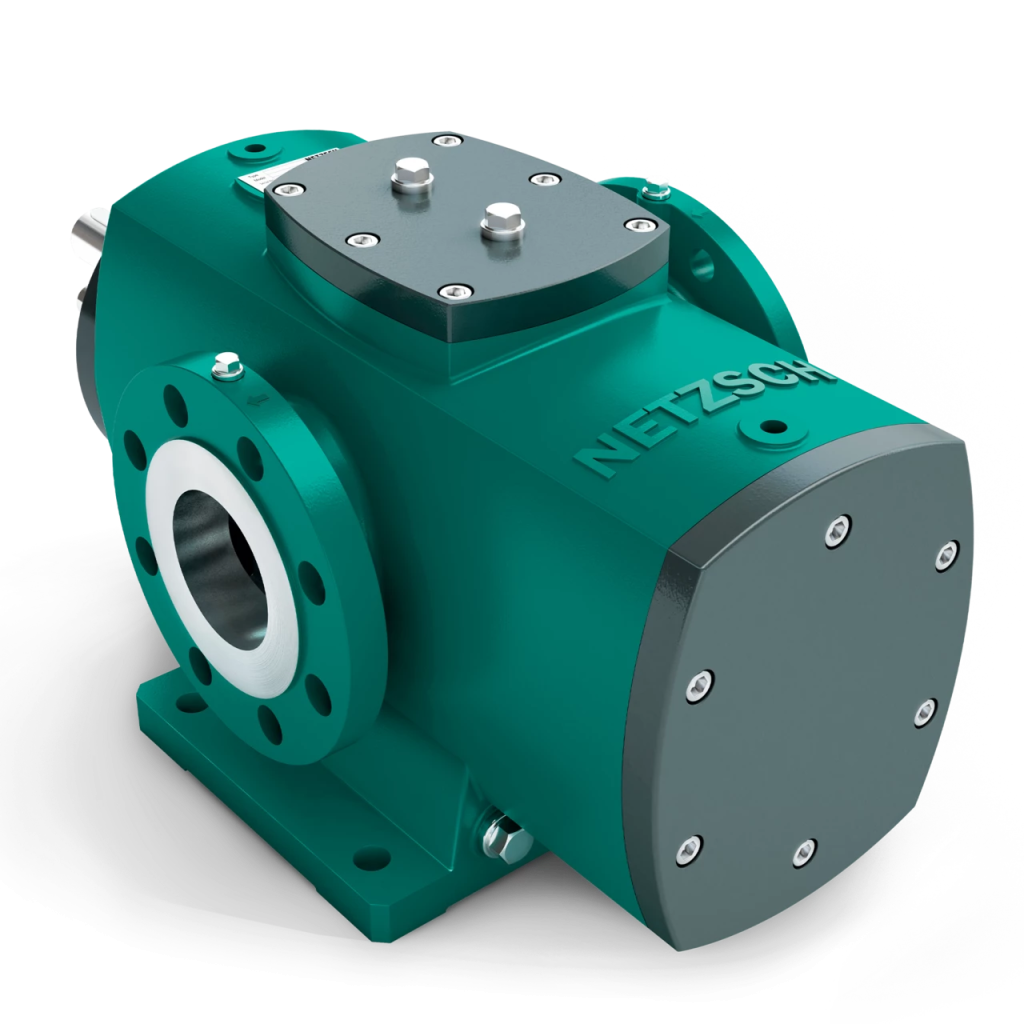

The three-screw pump is mainly composed of a bushing fixed in the pump body, an active screw inserted in the pump cylinder, and two driven screws meshing with it. Since the two driven screws mesh symmetrically with the active screw, the radial force acting on the active screw of the three-screw pump is completely balanced, and the active screw does not bear bending load. The radial force on the driven screw is supported by the pump cylinder bushing along its entire length, and no bearing is required at the outer end, and it basically does not bear bending load. The remarkable features of the three-screw pump are simple structure, small pressure pulsation, stable flow, stable and reliable operation, high speed, low noise, high efficiency, long life, and self-priming ability.

Advantages of progressive cavity pumps:

Wide pressure and flow range;

Wide range of types and viscosities of transported liquids;

High speeds can be used because the rotating parts in the pump have low inertia;

Good suction performance and self-priming ability;

Uniform and continuous flow, low vibration and low noise;

Less sensitive to incoming gas and dirt than other rotary pumps;

Solid structure and easy installation and maintenance.

Direct-Coupled Progressing Cavity Pumps in Industrial Design

What is a direct-coupled progressing cavity pump in industrial design ? Direct-connected progressive cavity pump has no bearing seat, and the prime Mover …

Food Grade Progressive Cavity Pumps

Food grade progressive cavity pump is also a kind of progressive cavity pump, its biggest feature is that the material can meet the requirements of food industry. The common material of current passing parts is stainless steel 304 and 316L, and the stator …

Stainless Steel Dosing Pumps for Dosing and Conveying

The dosing pump is a kind of progressive cavity pump, which is specially designed for small flow liquid transportation. Its structure is completely suitable for smooth and low pulsation medium transportation, and can accurately transport and measure corrosive and anti-corrosion chemicals.

Small Scale Progressive Cavity Pumps for Accurate Dosing

PMV Pump has launched a new progressive cavity pump designed specifically to enable the precise dosing of fluids and pastes proportionate to …