Vertical Progressive Cavity Pump

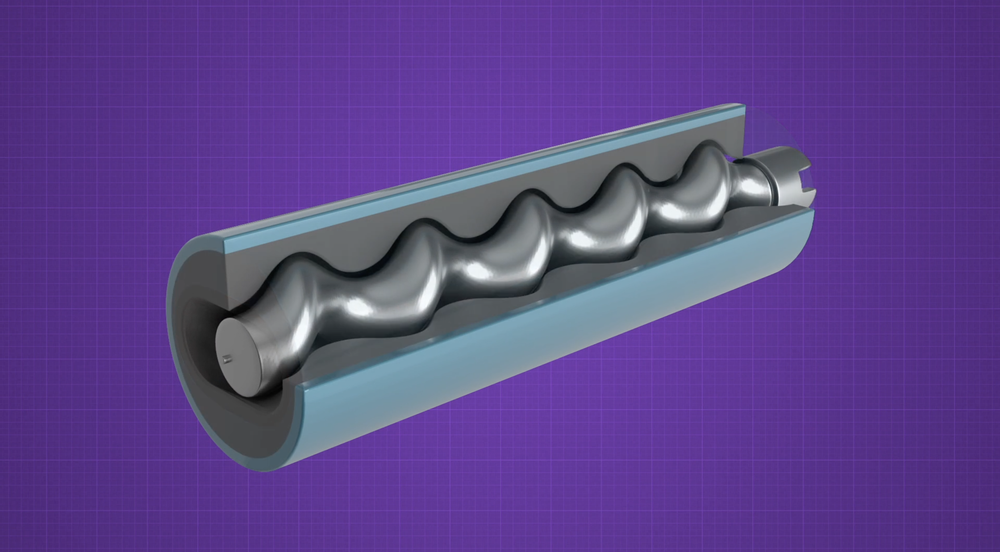

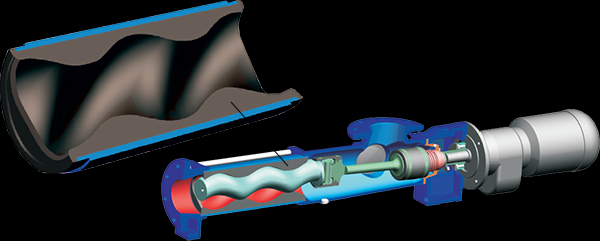

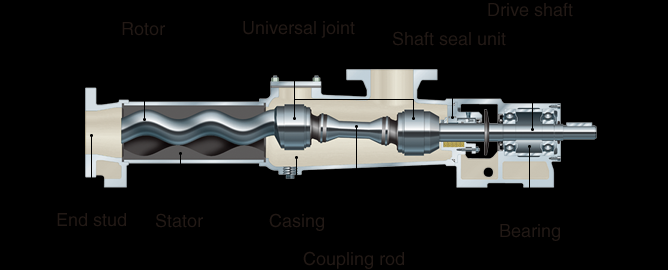

Vertical Progressive Cavity Pump Q=0.5-120m³/h (2.2 USGPM – 528 USGPM) P=0~1.2Mpa (0~175 psi) CONTACT What is a vertical progressive cavity pump? The vertical progressive cavity pump can be regarded as a horizontal progressive cavity pump working upright, and the inlet and outlet are exchanged. The biggest difference is that the stator of the suction inlet has a…