Parameters

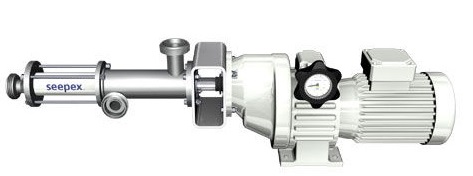

| Brand: SEEPEX | Performance: high pressure | Weight: 760kg |

| Pressure: 1.2Mpa | Transport medium: industrial sewage | Voltage: 380V |

| Pump shaft position: horizontal | Flow rate: 69m3/h | Application: booster pump |

| Impeller suction mode: single suction | Lift: 120m | Material: cast steel |

| Drive mode: electric | Working pressure: 1.2 | Model: BN130-12 |

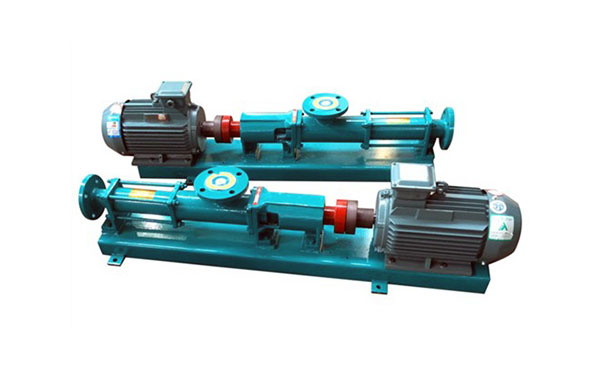

Seepex Brand Overview

Founded in the last century, Seepex focuses on providing high-quality pump solutions. Its products are widely used in the fields of chemical, food, pharmaceutical and environmental protection. Seepex has established a good industry reputation for its outstanding engineering technology and customer service. As one of its representative products, BN130-12L reflects Seepex’s deep accumulation in pump technology.

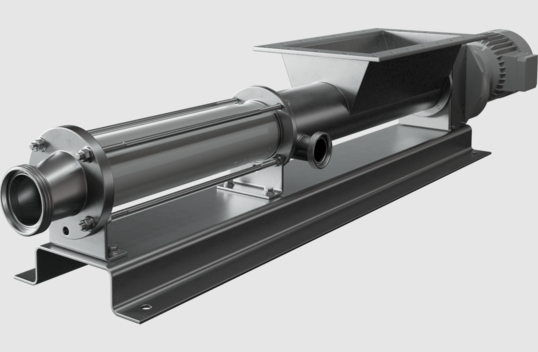

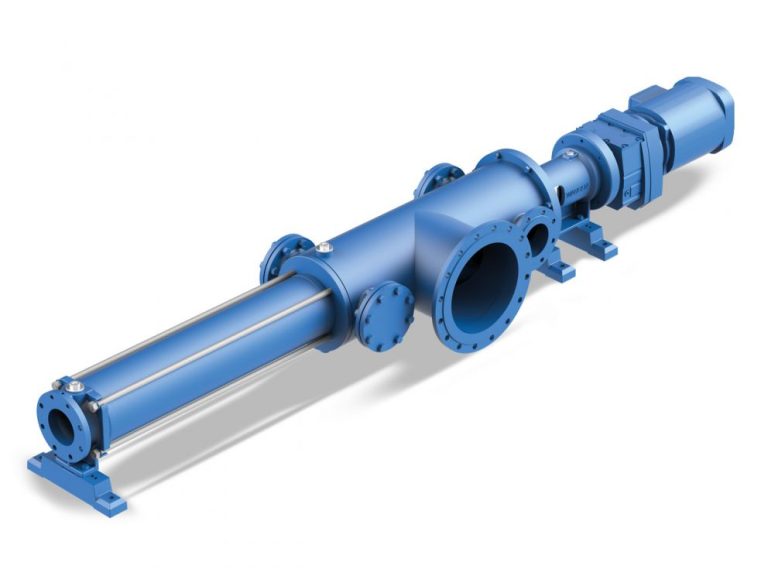

Design and Features of BN130-12L

The design of the BN130-12L pump fully considers the various needs of users. The specific features are as follows:

- Compact structure: The pump body is compactly designed, easy to install and maintain, and saves space.

- High-strength materials: Durable high-strength materials are used to ensure stable operation in harsh environments.

- Optimized fluid channels: The fluid channels are carefully designed to reduce the resistance of fluid movement and improve overall efficiency.

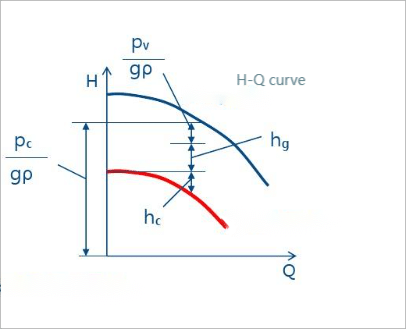

Performance advantages

The BN130-12L pump stands out in the market for its excellent performance. It has good self-priming ability and can achieve fast startup at low liquid levels. This allows the pump to maintain efficient working conditions when handling various fluids. In addition, the wear-resistant design of the pump extends the service life and reduces maintenance costs.

The BN130-12L rotor is a key component of the BN130-12L pump. Its design determines the flow and pressure characteristics of the pump. The rotor adopts a spiral design, which can form a certain volume change during rotation, thereby realizing continuous fluid delivery. The material of the rotor usually has good wear resistance and can withstand the influence of high temperature and corrosive fluids.

The BN130-12L stator is an important component that matches the rotor and is usually made of elastic material to ensure the sealing between the rotor and the rotor. The inner surface of the stator is specially treated to effectively reduce the friction of the fluid in the pump, thereby improving the working efficiency of the pump.

Application areas

BN130-12L pumps are widely used in many industries. The following are the main application areas:

| Pharmaceutical industry: excels in precise flow control. |

| Chemical industry: suitable for handling various corrosive liquids. |

| Food industry: meets hygiene standards and ensures food safety. |

| Environmental protection field: effectively treats sewage and waste liquid. |

Maintenance and care

In order to ensure the long-term and efficient operation of the BN130-12L pump, regular maintenance and care are indispensable. The main maintenance points include:

- Regularly check the sealing: ensure that the pump has good sealing performance to prevent leakage.

- Clean the pump body and inlet and outlet: regularly clean the pump body and flow channel to prevent impurities from blocking and affecting the flow.

- Check the motor and transmission system: regularly check the motor and transmission parts to ensure their normal operation.

Cost-Benefit Analysis

Although the initial investment of the BN130-12L may be high, its economic benefits in the long run are significant. Users should consider the following factors when selecting a pump:

- Reduce energy consumption: Efficient operation can significantly reduce electricity consumption.

- Reduce maintenance costs: The wear-resistant design reduces equipment failures and downtime.

- Improve production efficiency: The efficient performance of the pump directly improves the overall efficiency of the production line.

people also ask

Send Your Enquiry :