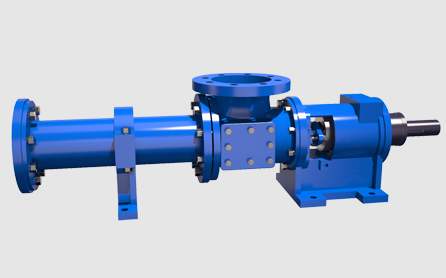

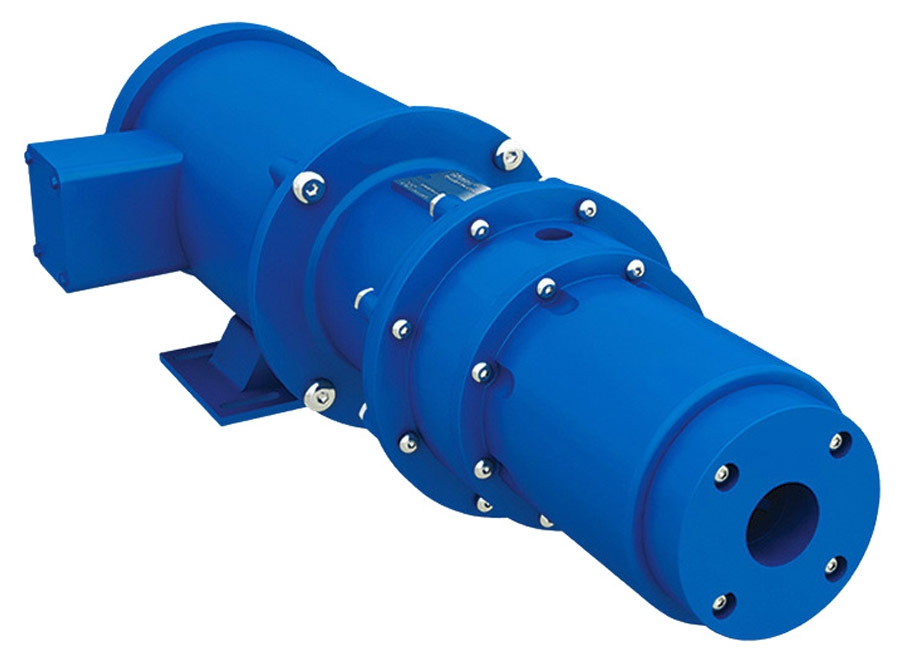

Magnetic Drive Progressive Cavity Pumps

Progressive cavity pumps are well-regarded for their unique design and operational efficiency. When combined with magnetic drive technology, they offer significant advantages in various industrial applications. This article explores the features, benefits, and applications of magnetic drive progressive cavity pumps.

What are Magnetic Drive Progressive Cavity Pumps?

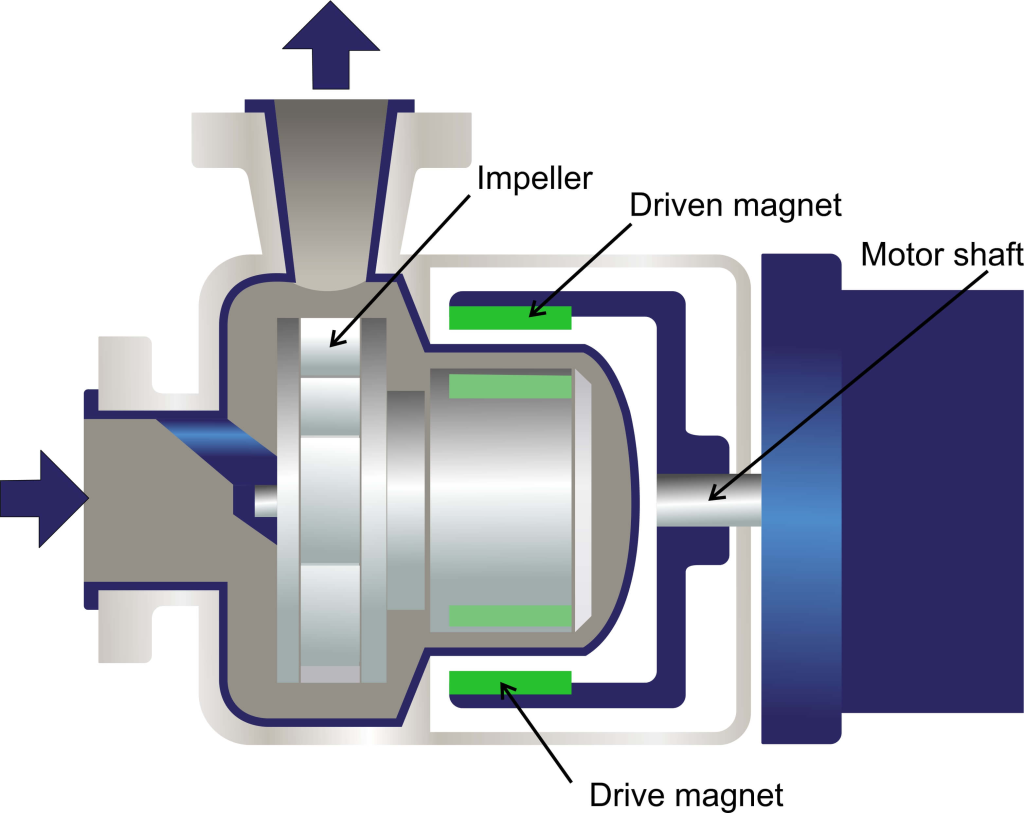

Magnetic drive progressive cavity pumps utilize a helical rotor and stator configuration, which allows for a continuous flow of fluid. The magnetic drive mechanism eliminates the need for traditional mechanical seals, reducing maintenance needs and enhancing reliability.

Key Features

- Sealless Design: The magnetic drive eliminates mechanical seals, which are common failure points in traditional pumps.

- Gentle Handling of Fluids: The design allows for the gentle transfer of fluids, making it ideal for shear-sensitive materials.

- Wide Viscosity Range: These pumps can handle fluids with varying viscosities, from thin liquids to thick slurries.

- Configurable: They can be adapted for various applications with different rotor and stator materials.

Advantages

- Reduced Maintenance: With fewer moving parts and no mechanical seals, the maintenance requirements are significantly lower.

- Increased Safety: The sealless design reduces the risk of leaks, making these pumps a safer option for hazardous substances.

- Energy Efficiency: The progressive cavity design allows for efficient fluid transfer, leading to lower energy consumption.

- Extended Lifespan: The robust construction and lack of mechanical wear points contribute to a longer operational life.

Applications

Magnetic drive progressive cavity pumps are versatile and can be used in various sectors, including:

- Chemical Processing: Ideal for transferring corrosive chemicals without the risk of leakage.

- Food and Beverage Industry: Suitable for handling food products where hygiene is paramount.

- Wastewater Treatment: Efficient for pumping sludge and other viscous waste materials.

- Pharmaceuticals: Ensures the gentle handling of sensitive compounds without contamination.

Conclusion

Magnetic drive progressive cavity pumps represent a significant advancement in pump technology. Their unique design and operational benefits make them an excellent choice for a wide range of applications. By choosing these pumps, industries can achieve greater efficiency, safety, and reliability, ultimately leading to improved productivity and reduced operational costs. As technology continues to evolve, these pumps will likely play an increasingly vital role in various sectors, ensuring the effective and safe transfer of fluids.

Send Your Enquiry :