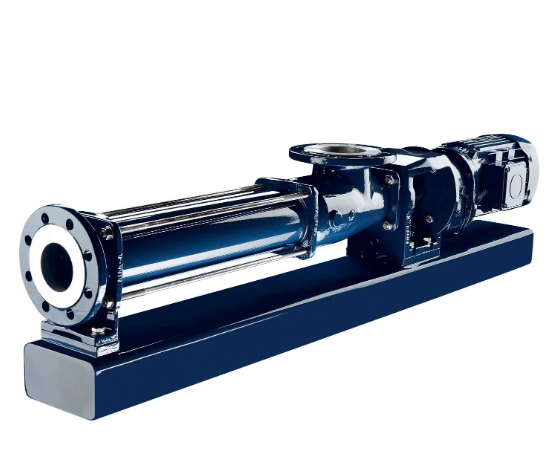

SEEPEX – N Range Standard Pumps

Product group N pumps come in 2 ranges and are the basis for all SEEPEX progressive cavity pumps. It conveys thin to viscous media, with or without solids, up to approximately 10% dry solids content.

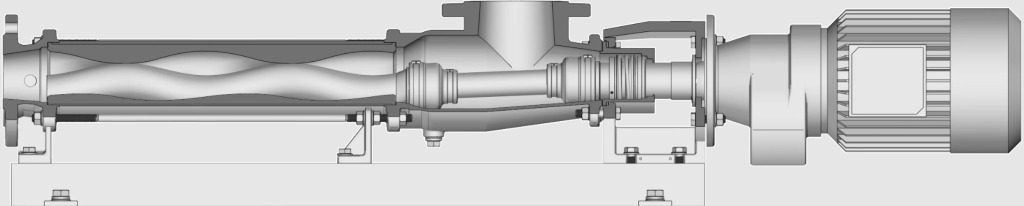

The Description of SEEPEX – N Range Standard Pumps

Product group N pumps are the basis for SEEPEX progressive cavity pumps. They are used in almost all industrial sectors and convey low to highly viscous media with or without solids. Those benefits along with others ensure the pump’s economical operation.

Properties & Benefits:

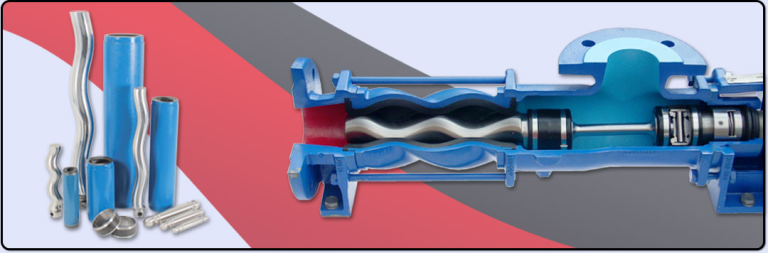

- Various rotor/stator geometries (conventional, 6L and Tricam geometry)

- Low pulsation, uniform flow

- High self-priming capabilities even with a mixture of liquid and air or gas up to a 9 meter water column

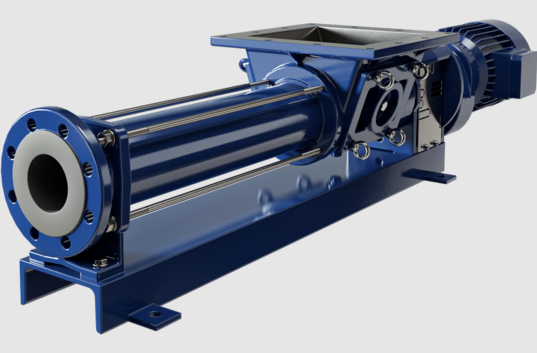

- Numerous installation options

- Large spherical entrance port

- Reversible rotation and flow

Application of SEEPEX N Range Standard Pumps

SEEPEX N Range Standard Pumps are widely used in various industries for their exceptional performance and reliability. With their robust construction and advanced design, these pumps are ideal for handling a variety of liquids, including viscous, abrasive, and shear-sensitive fluids.

Whether it’s for transfer, metering, or dosing applications, SEEPEX N Range Standard Pumps offer unparalleled efficiency and precision. They can handle flow rates ranging from 0.2 to 500 m³/h and pressures up to 36 bar. Their modular design allows for easy customization and integration into existing systems.

Some common applications of SEEPEX N Range Standard Pumps include food and beverage processing, chemical manufacturing, wastewater treatment, and oil and gas production. In the food industry, these pumps are used for transferring delicate products like yogurt and cream cheese, while in the chemical industry, they are used for precise dosing of acids and bases. In the oil and gas industry, they are used for injection of chemicals and other additives.

Overall, SEEPEX N Range Standard Pumps are a versatile and reliable choice for a wide range of fluid handling applications.

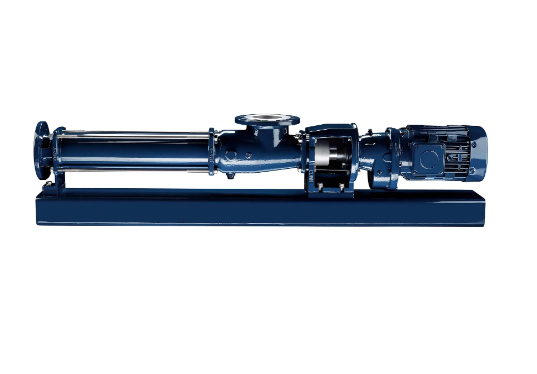

The Features of SEEPEX – N Range Standard Pumps

- Convey capacity: Up to 2,200 US GPM (up to 500 m3/h)

- Pressure: Up to 1,400 psi (up to 96 bar)

- Various rotor / stator geometries (conventional, 6L, Tricam)

- Minimal pulsation, uniform flow

- High self-priming capabilities even with a mixture of liquid and air / gas up to a 9 m (29.5 ft.) water column

- Low shear rates

- Numerous installation options

- Large spherical entrance port

- Reversible rotation and flow

- Variable speed, flow is directly related to pump speed

People Also Ask

Send Your Enquiry :