[wpseo_breadcrumb]

WITH JOINTLESS, ONE-PIECE ROTATING UNIT MADE OF WEAR RESISTANT SYNTHETIC MATERIAL

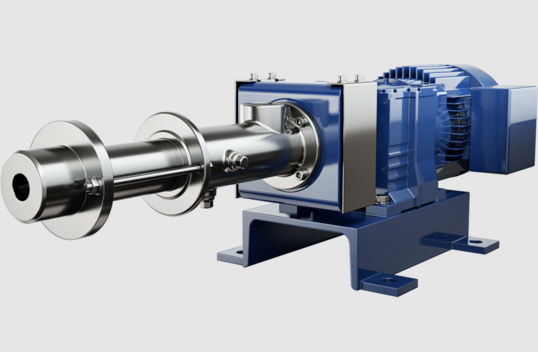

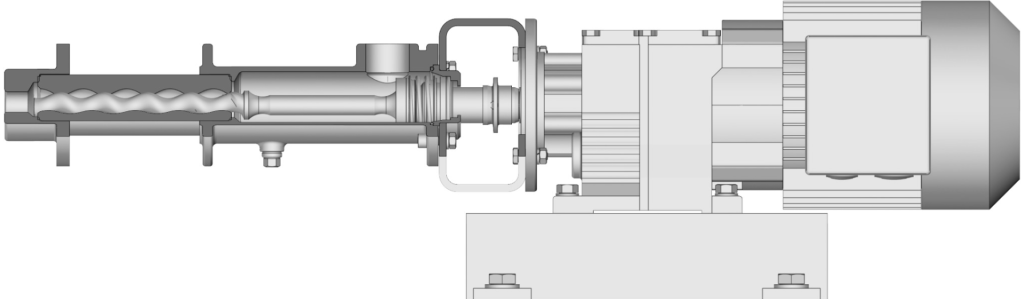

SEEPEX MDP range pumps have one-piece rotating units made of wear resistant synthetic material, making them suitable for conveying hydrocarbon-containing media such as paints, varnishes, solvents, plasticizers and others.

Description of SEEPEX MDP – ECONOMICAL METERING PUMP

SEEPEX MDP – Economical Metering Pump is a compact and reliable pump designed for accurate metering and dosing of liquids in various industries. Its modular concept allows for easy installation and maintenance, while its stainless steel construction ensures resistance to corrosion and wear. With a range of flow rates and pressures and a smart control system, this pump provides precise control over processes, improving efficiency and reducing waste. It is an ideal choice for those looking for a cost-effective and efficient solution for liquid metering and dosing needs.

Efficient Metering with SEEPEX MDP Economical Metering Pump

The SEEPEX MDP Economical Metering Pump is an ideal solution for efficient and accurate metering in various applications. Its innovative design allows for precise dosing of a wide range of liquids, from chemicals to food products. The pump’s high suction capacity ensures consistent flow rates, while its low pulsation minimizes product shear and foaming.

Whether used in water treatment, chemical processing, or food and beverage production, the SEEPEX MDP is a reliable choice for metering applications. Its easy-to-use interface and robust construction make it a cost-effective alternative to more expensive systems.

Investing in the SEEPEX MDP can help improve efficiency, reduce waste, and maximize productivity in a variety of industries. With its advanced technology and economic design, this metering pump is a smart choice for businesses looking to optimize their operations.

Economical

Reduced costs due to inexpensive rotating unit

No vapor locking

Cavity design allows for conveyance of liquids, solids, and gases

Ease of operation

Valveless flow control for ease of operation

Performance efficiency

Low slip (internal back flow) provides performance efficiency and less wear on components

Easy maintenance

Simple and predictive maintenance due to minimal components

Lightweight

The rotating unit and housing, made of wear resistant synthetic material, lower the pump’s overall weight

Flexible equipment

The pump can be made from various materials of construction

People Also Ask

Send Your Enquiry :