The Description of Cavity Pumps.

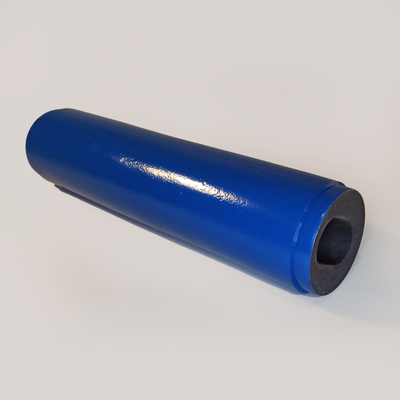

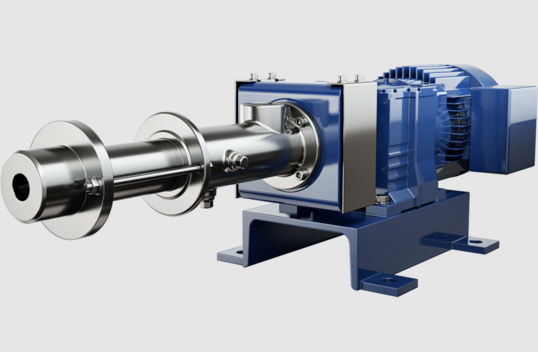

PMV Cavity pumps, also known as progressive cavity pumps or PC pumps, are positive displacement pumps that use a helical rotor and a stator to create a series of cavities that move fluid from the inlet to the outlet.

The Working Principle of Progressive Cavity Pumps.

How does progressive cavity pump work?

The rotor’s helical shape fits tightly inside the stator, creating a sealed cavity that moves fluid through the pump. As the rotor turns, the cavities progress along the stator, resulting in a pumping action.

Cavity pumps offer several advantages, including high suction capability, ability to handle viscous fluids, self-priming ability, and gentle handling of shear-sensitive materials. They are also known for their ability to handle fluids with high solids content.

Application about Progressive Cavity Pumps.

Cavity pumps are widely used in various industries for handling viscous and abrasive fluids, such as oil, slurry, and wastewater. They are particularly beneficial in applications where high pressure and consistent flow rate are required.

The Features of Progressive Cavity Pumps.

High Efficiency: Cavity pumps are designed to deliver high pumping efficiency and smooth flow, ensuring optimal performance in pumping applications.

Versatility: These pumps can handle a wide range of fluids, including those with high solids content, making them suitable for diverse industrial applications.

Gentle Handling: Cavity pumps provide gentle handling of fluids, preventing damage or degradation of sensitive materials during pumping.

Self-Priming: With their self-priming capability, cavity pumps eliminate the need for additional priming equipment, simplifying operation and minimizing downtime.

Low Maintenance: These pumps have a simple construction with fewer moving parts, reducing the need for frequent maintenance and minimizing operational costs.

Send Your Enquiry :