NETZSCH Pumps Universal Parts

High-quality replacement parts for NETZSCH Pumps–PC Pumps

Complete Models, Good Matching, Fast Delivery!

NETZSCH Pumps Replacement Parts

NETZSCH is a global specialist in complex fluid management. They have supplied positive displacement pumps worldwide for more than 60 years. NETZSCH pumps are widely applied in the fields of Food/Pharmaceutical, Mining, Chemical, Pulp/Paper, Environment/Energy, Oil/Gas upstream, etc. NETZSCH PC pumps are popular in the market as well as SEEPEX PC pumps and MONO PC pumps.

Among the NETZSCH pumps, their progressing cavity pumps are very popular and used in most countries. During the pumping work, the rotor, stator and some other components would be worn naturally or damaged due to some problems. Then the users need to replace the original spare parts or need some good quality replacement parts instead.

PMV PUMP can supply such high-quality replacement parts for NETZSCH progressing cavity pumps. We can provide the replacement spare parts with complete models, good matching and fast delivery. They are generic parts for NETZSCH PC pumps. The generic parts we supplied for NETZSCH pumps can highly match the original pump parts and be with equivalent service life.

NETZSCH Spare Parts–Replacement Parts

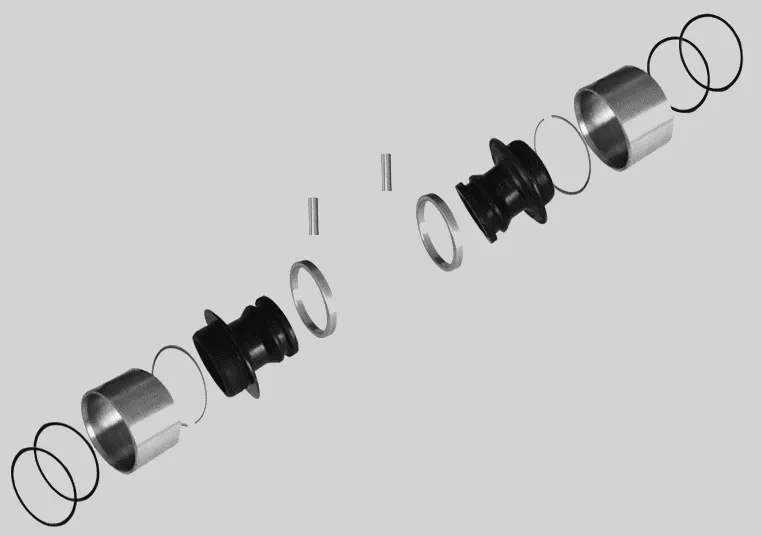

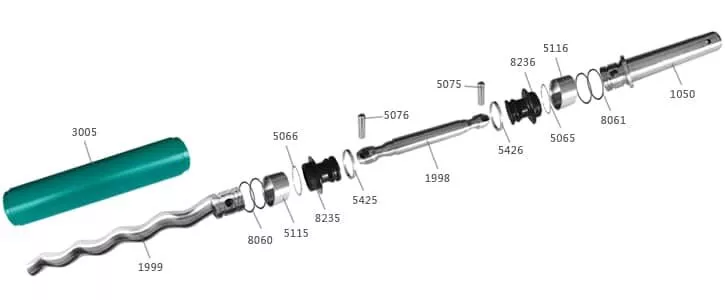

Generally, we supply the whole set of replaceable accessories for NETZSCH processing cavity pumps. The replacement components include the helical rotor, stator, drive shaft, coupling rod, universal joint set and mechanical seal/packing seal. They normally are available in separate parts or a whole set.

Replacement Parts Available for NETZSCH Pumps

Material Optional: SS304/SS316L/DSS/Tool Steel Plating Optional: Cr Plating/Tungsten Carbide

Shell Optional: Steel/Stainless Steel Lining Optional: NBR/EPDM/FKM/HNBR/PTFE

Material Optional: SS304/SS316L/DSS/Tool Steel Shaft Type: Bolt Coupling/Cross-Coupling

Material Optional: SS304/SS316L/DSS/Tool Steel Plating Optional: Cr Plating/Tungsten Carbide

Include Sealing Covers, Retaining Sleeves,

Coupling Rod Pins, Snap Rings, O-rings, etc.

Mechanical: Long life, good anti-viberation Packing seal: low cost, easy to install&replace

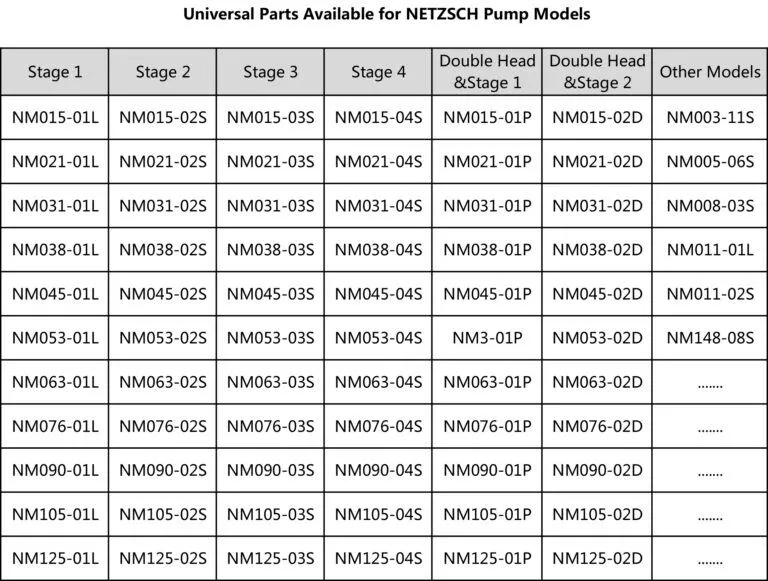

Universal Parts Available for NETZSCH Pump Models

Top Level Intl. can supply the whole set of interchangeable parts for NETZSCH progressing cavity pumps. The universal replacement parts are the rotor, stator, drive shaft, coupling rod, universal joint set and mechanical seal/packing seal, etc.

The universal parts normally are available in separate parts or a whole set. Please don’t hesitate to let us know the pump models and replacement part numbers or names when you are interested in any cavity pump parts.

People Also Ask

Send Your Enquiry :