Netzsch NM015BY02S12B Rotor

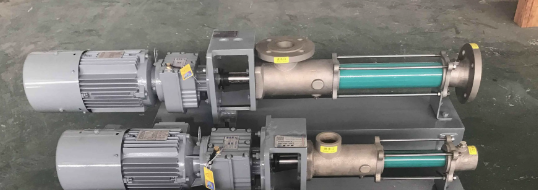

As a widely used conveying equipment, the core components of the screw pump include the rotor and the stator. Netzsch NM015BY02S12B is a screw pump suitable for low-flow conveying. Its optimized rotor design is the key to ensure its high efficiency.

Rotor design

The rotor of NM015BY02S12B adopts a special design of double helical teeth. This structure not only improves the sealing of the pump cavity, but also significantly reduces the friction loss between the rotor and the fluid. The rotor size is suitable for conveying various fluids with low flow.

Another key design highlight is the smooth polishing of the rotor surface. This fine surface treatment further reduces the friction between the rotor and the fluid, thereby improving the conveying efficiency and service life of the whole machine. The choice of special alloy material also provides a guarantee for the durability of the rotor.

Perfect match

The stator is made of special rubber, which has a certain elasticity and can be precisely matched with the rotor to ensure good sealing of the pump cavity. The spiral shape of the stator and the rotor is perfectly matched. The precise matching of the rotor and stator is the key to the high performance of the NM015BY02S12B screw pump. The perfect matching of the rotor made of special alloy and the rubber stator ensures the tight sealing of the pump cavity, reducing leakage and energy loss.

The key to NM015BY02S12B’s ability to stand out in the field of low-flow delivery lies in its optimized rotor design. Special material selection, precise size matching and smooth structural shape make NM015BY02S12B show excellent efficiency and reliability in rotor transmission.

People also ask

Send Your Enquiry :