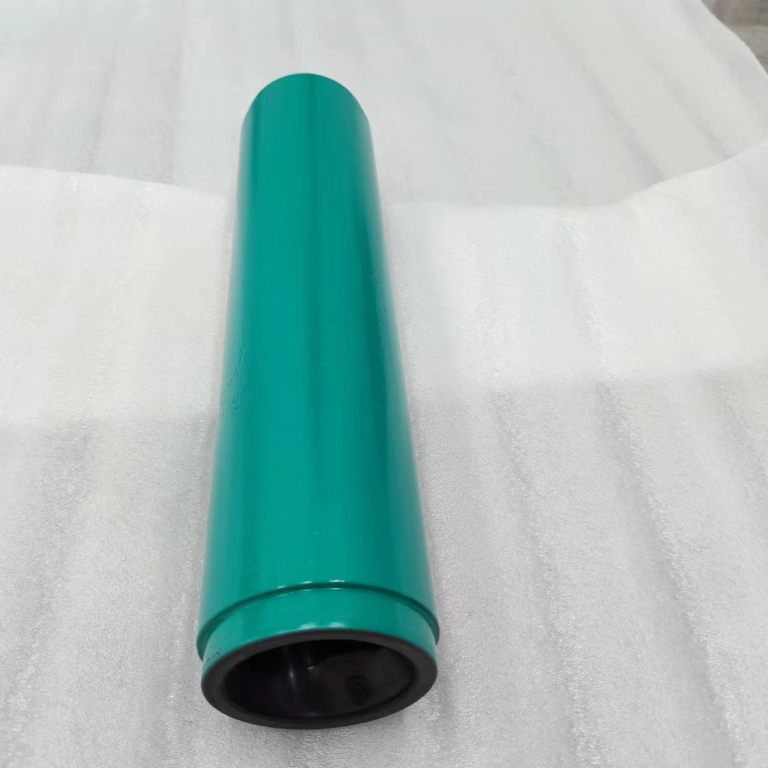

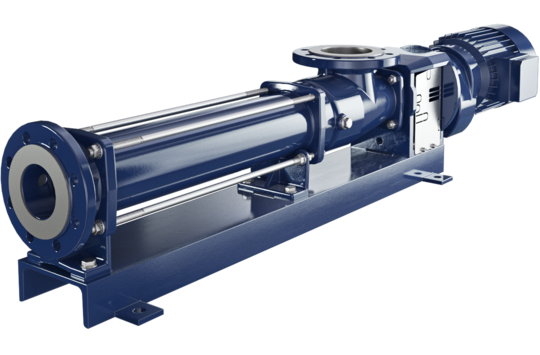

BN2-6L stator seepex

Design Advantages

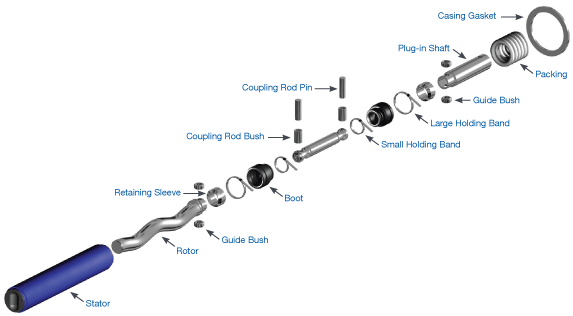

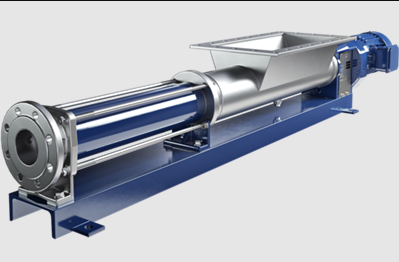

The Seepex BN2-6L stator uses advanced screw pump technology and is designed to meet various complex fluid delivery needs. The main advantages of this stator are its durability and adaptability. First, the Seepex BN2-6L stator is made of highly wear-resistant and corrosion-resistant synthetic materials that can withstand harsh working environments. This not only increases its service life, but also reduces maintenance frequency and saves the company’s operating costs.

Secondly, the stator uses an optimized geometric design to ensure that it can maintain a stable flow output even when running at low speeds. This is especially important in applications where the fluid delivery speed and pressure need to be controlled. In addition, the sealing technology used in the Seepex BN2-6L stator effectively prevents fluid leakage and improves the safety of the overall system.

Application Areas

- Food and Beverages

The food and beverage industry has extremely high requirements for product quality and safety. The hygienic design of the Seepex BN2-6L stator meets the safety standards of the food industry and can prevent contamination of the fluid during delivery. This feature makes it widely used in the production process of foods such as juice, dairy products, and syrups to ensure the quality of the final product. At the same time, the design optimization enables it to perform well in handling viscous fluids and maintain a stable flow output. - Sewage treatment

In the environmental protection and sewage treatment industries, the Seepex BN2-6L stator is used to transport sewage and sludge. Its ability to handle high solid content and high viscosity fluids helps reduce the energy consumption of sewage treatment systems while improving treatment efficiency. This field of application makes the Seepex BN2-6L stator essential for urban and industrial sewage treatment.

- Coating and plastic production

In the production process of coatings and plastics, the Seepex BN2-6L stator also demonstrates its excellent performance. It can efficiently transport various types of coatings, including viscous paints and plastic raw materials, while ensuring flow and pressure, and avoiding separation and precipitation of the media. - Chemical industry

In the chemical industry, the Seepex BN2-6L stator is particularly widely used. The device is capable of handling a variety of chemicals, including acids, alkalis, and other high-viscosity fluids. Due to its excellent corrosion resistance, the Seepex BN2-6L stator is suitable for conveying harsh chemical media, ensuring safety and stability during the production process. In addition, the fast fluid delivery capability improves production efficiency and ensures efficient operation of the chemical process.

people also ask

Send Your Enquiry :