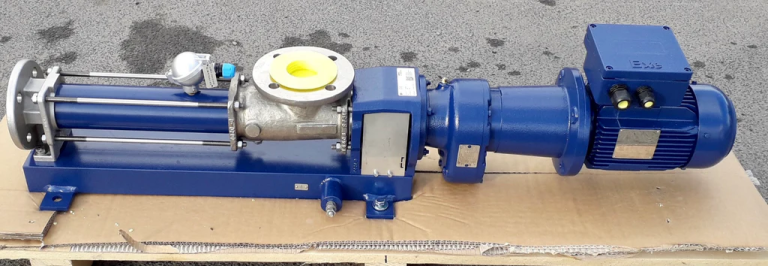

BN17-6L rotor seepex

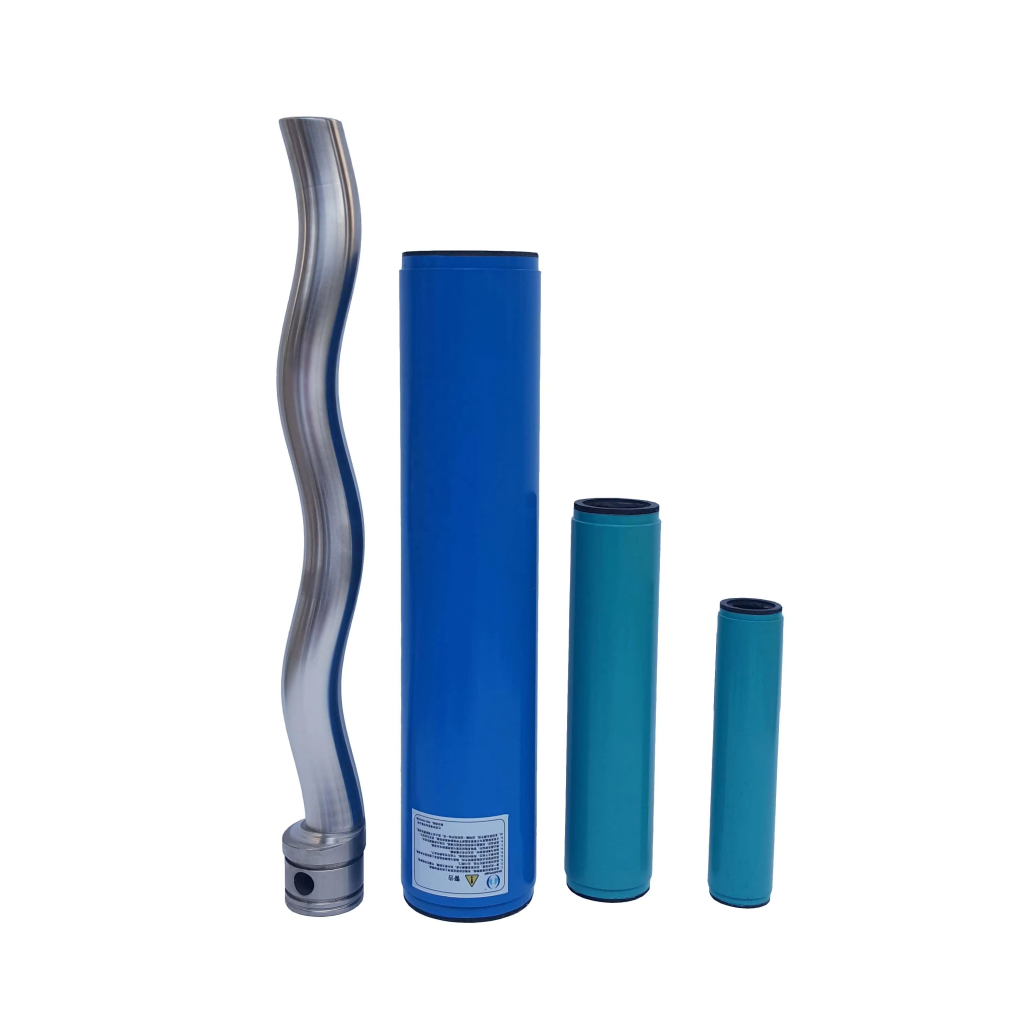

Structural features of the Seepex BN17-6L Rotor

The Seepex BN17-6L Rotor is a screw pump rotor with a unique geometric design that enables efficient operation during fluid delivery. The rotor material is usually made of wear-resistant, high-strength alloys, which can effectively improve its durability in high-pressure and high-temperature environments.

The key to this rotor design is its spiral structure, which can generate continuous propulsion when rotating to ensure uniform fluid delivery. Compared with traditional pumps, the Seepex BN17-6L Rotor can handle more viscous fluids while effectively reducing flow resistance and improving overall efficiency.

Wide range of applications

The application range of Seepex BN17-6L Rotor is very wide, mainly covering the following fields:

- Chemical industry: In the chemical production process, it is often necessary to handle high-viscosity chemical raw materials or intermediate products. Seepex BN17-6L Rotor can efficiently transport these fluids to ensure the smooth operation of the production line.

- Food and beverage: In the food processing industry, this rotor is often used to gently transport liquid ingredients such as syrups and juices. Its design ensures the safety of food and avoids damage to fluid components.

- Wastewater treatment: In the sewage treatment system, Seepex BN17-6L Rotor can effectively deal with fluids containing solid particles to ensure the stable discharge and treatment of sewage. This feature is particularly important in the field of environmental protection.

- Pharmaceutical industry: The pharmaceutical process has extremely high requirements for the delivery accuracy of fluids. The stable performance of Seepex BN17-6L Rotor just meets this demand, ensuring the quality and production efficiency of drugs.

Advantages

The advantages of using the Seepex BN17-6L Rotor are numerous, including:

High efficiency: Due to its unique design, the rotor can achieve high flow output with low energy consumption, reducing operating costs.

Strong durability: The use of high-strength materials allows it to maintain good performance even in harsh environments, reducing the frequency of maintenance and replacement.

Wide adaptability: With comprehensive functions, it can handle a variety of fluid types, including fluids with high viscosity and solid particles.

Small footprint: Due to its compact design, the Seepex BN17-6L Rotor can be installed in many space-constrained environments.

Easy maintenance: The design of the rotor allows users to easily perform daily inspections and maintenance, extending the service life of the equipment.

people also ask

Send Your Enquiry :