[wpseo_breadcrumb]

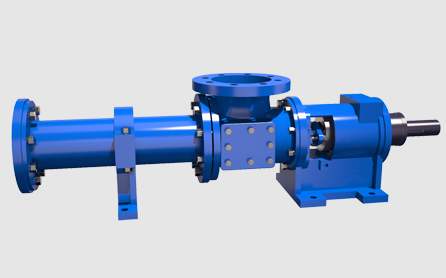

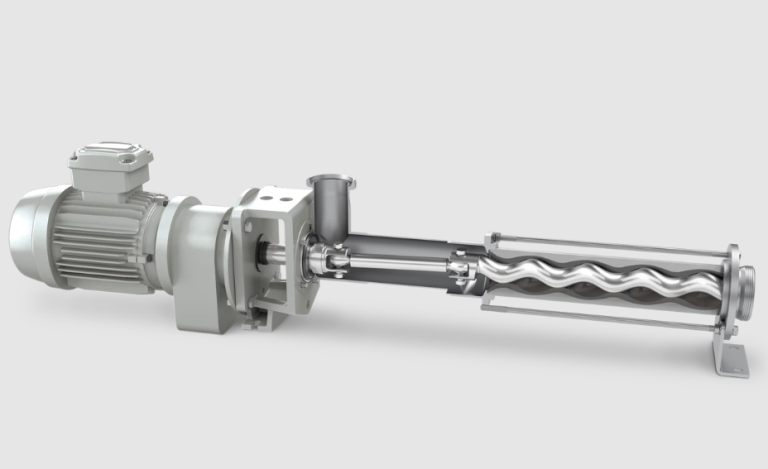

Design and Features of Seepex BN200-6L Rotor

The Seepex BN200-6L rotor is a rotor that uses screw pump technology and has powerful fluid handling capabilities. This pump rotor can effectively reduce the shear force of the fluid in the pump through the precise spiral structure design, ensuring that its original characteristics are maintained when conveying viscous or particulate fluids.

The design of this rotor emphasizes sealing and wear resistance, and uses high-quality materials to reduce wear, thereby increasing the service life of the pump. In addition, its compact structure makes installation and maintenance more convenient.

Performance Features

- High efficiency

The design of the seepex BN200-6L rotor enables efficient flow delivery and minimizes energy loss. Whether it is low or high flow requirements, this rotor can meet the requirements with stable performance. - Wear resistance

In many industrial applications, the fluid may contain solid particles, which will cause wear on the operation of the pump. The materials and coating technology used in the BN200-6L rotor significantly improve its wear resistance, thereby extending the service life of the equipment. - Strong adaptability

The versatile design of the seepex BN200-6L rotor enables it to adapt to different types of media. This adaptability makes its application in various industries particularly convenient, without the need for frequent adjustments or replacement of equipment. - Simple maintenance

The design of this rotor not only optimizes performance, but also simplifies the maintenance process. Users can easily perform daily inspections and necessary maintenance, greatly reducing downtime and maintenance costs.

Scope of application

The Seepex BN200-6L rotor is suitable for a variety of industries, and its main application areas include:

Chemical industry:

In the process of chemical reactions, it is often necessary to pump viscous or granular fluids. Seepex's design can efficiently handle these types of media to ensure the smooth progress of the reaction.

Wastewater treatment:

In sewage treatment plants, sediments and activated sludge need to be transported. The powerful ability of Seepex BN200-6L can cope with sewage with complex components to ensure the effectiveness of the treatment process.

Food processing:

In the process of food production, hygiene and safety are top priorities. Seepex's screw pump rotors are made of non-polluting materials, meet food hygiene standards, and are suitable for handling a variety of food raw materials.

people also ask

Send Your Enquiry :