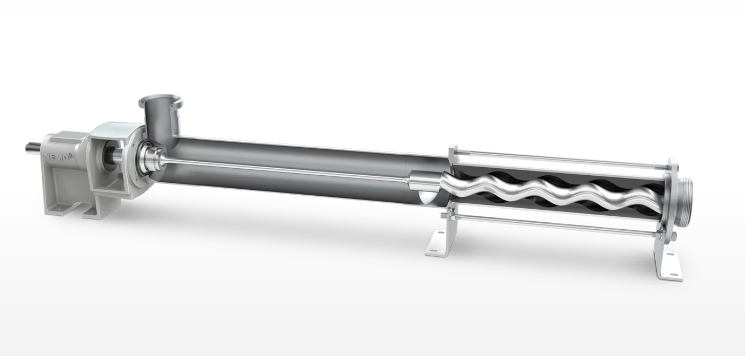

BN2-12L rotor seepex

Unique rotor design improves operational reliability

seepex BN2-12L adopts a unique rotor design, which can effectively improve the operational reliability of the pump. Unlike traditional diaphragm pumps, it does not use metal rotors, but is made of high-performance engineering plastics. This material is not only reliable and durable, but also has excellent corrosion resistance, which greatly extends the service life of the pump.

At the same time, the BN2-12L rotor adopts a fully sealed structure, which effectively avoids the problem of medium leakage. This not only protects the internal structure of the pump, but also ensures the safety of the operator. In addition, the smooth surface of the rotor can minimize the friction between the plunger and the pump body, further reducing the need for maintenance and repair.

Application areas

The BN2-12L rotor is widely used in the following fields due to its excellent conveying capacity and wide applicability:

Food and beverage industry: It can convey various viscous and easily deformed food raw materials, such as jam, chocolate sauce, honey, etc.

Pharmaceutical industry: It can gently convey various pharmaceutical raw materials, such as creams, gels, etc., without destroying the chemical properties of the materials.

Chemical industry: Suitable for conveying various chemicals, such as dyes, resins, paints and other fluids with high viscosity and corrosiveness.

Sewage treatment: Reliably convey sewage sludge containing particles and fibers, effectively preventing pump blockage.

Building materials industry: Suitable for conveying high-viscosity building materials such as cement slurry and mortar.

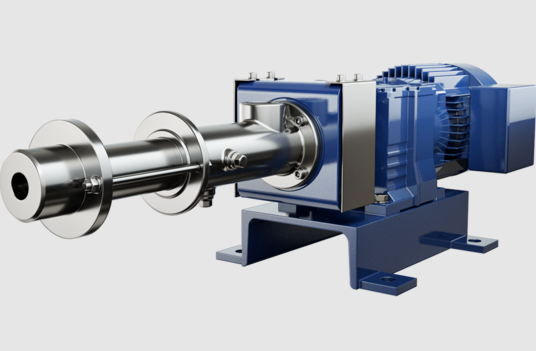

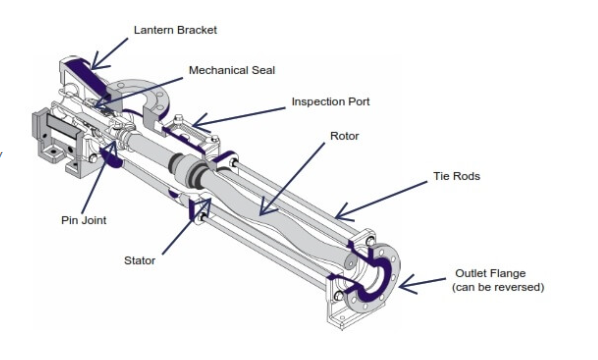

Technical characteristics

The seepex BN2-12L rotor stands out in industrial applications with the following technical characteristics:

Strong wear resistance: The pump body is made of high-alloy steel material, with patented rotor and rotor shell design, which can effectively resist various wear and tear and greatly extend the service life.

Good anti-clogging performance: The unique rotor design can easily convey media containing impurities such as particles and fibers to avoid pump blockage problems.

Excellent self-priming performance: The pump body is equipped with a self-priming device, which can autonomously suck in media under negative pressure without the need for an additional suction pump.

Low pulsation and low noise: Smooth rotor operation ensures low pulsation and low noise characteristics during transportation.

High efficiency and energy saving: The precise rotor and rotor shell design greatly improves the energy utilization efficiency of the pump and reduces operating costs.

Easy maintenance and repair: The pump body has a simple and compact structure, and maintenance and repair work can be completed quickly and efficiently.

Product advantages

Compared with other similar pump products, the seepex BN2-12L rotor has the following outstanding advantages:

Wide range of application: With excellent wear resistance and anti-clogging properties, the seepex BN2-12L pump can be widely used in various industrial fields to meet the diverse needs of users.

Excellent performance: Excellent self-priming ability, low pulsation characteristics and high efficiency and energy saving performance ensure the stability and reliability of the pumping process.

Long service life: The sturdy and durable materials and structural design greatly extend the service life of the pump and reduce long-term operating costs.

Easy maintenance: The compact structural design makes the maintenance and repair of the pump body simple and efficient, reducing the maintenance burden of users.

Environmental protection and energy saving: Excellent energy utilization efficiency not only saves operating costs, but also contributes to the sustainable development goals of users.

people also ask

Send Your Enquiry :