[wpseo_breadcrumb]

OEM service/Custom Manufacturing

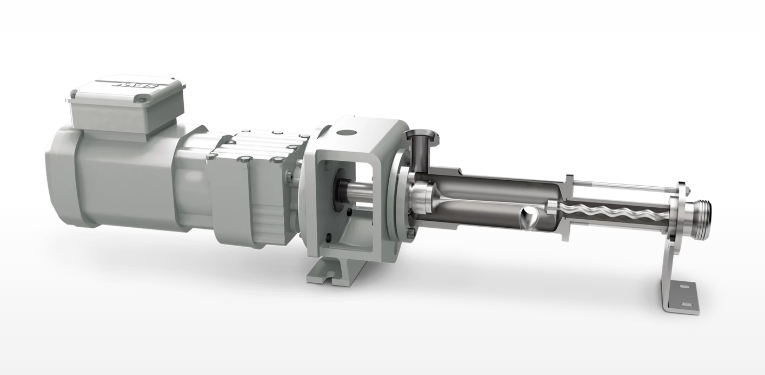

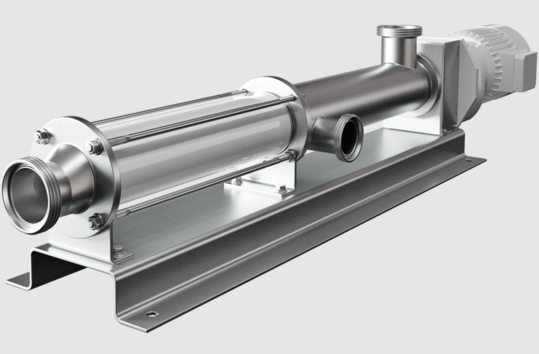

By working hard and smart in the CNC machining field for over 20 years, PMV Pump. can supply customers with high-quality CNC machined parts for various applications. Besides standard replacement spare parts and bareshaft pumps for NETZSCH/MONO/SEEPEX PC pumps, we are also proud to offer top-quality OEM services and custom manufacturing for progressive cavity pump parts.

The OEM pump parts include helical rotors, stators, coupling rods, driving shafts, other parts of the universal joint sets, etc.. With our expertise and dedication to meeting our customer’s unique requirements, we can provide tailored solutions that precisely match your specific needs.

Our team of skilled professionals excels at translating customers’ drawings or samples into high-quality progressive cavity pump parts. Whether you require modifications to existing designs or entirely new components, we have the capability to deliver exceptional results. We understand the importance of accuracy and precision in the manufacturing process, ensuring that the final products meet the highest standards of performance and durability.

Quality Control Before Delivery

Quality is superior to everything!PMV Pump knows how important a good quality and reliable reputation is in the business and stable cooperation. And we care about the customer’s quality and reputation as they do to win more projects and market segments.

Every part of the progressive cavity pump, no matter if they are standard replacement spare parts or custom PC pump parts, would be strictly and professionally inspected to guarantee quality before we ship them out.

For helical rotors and elastomer stators, we also check the compatibility by matching them with each other. That’s why our customers are satisfied with our products and services. Start a project with us now, we won’t let you down.

Benefits of Our Custom Manufacturing

PMV Pump has over 20 years of experience in custom CNC machining. We have customized a large number of parts according to customers’ drawings, samples, and even their ideas. Normally, we not only manufacture bespoke parts for our customers but also give practical suggestions and tailored solutions for their specific needs. By choosing our OEM service or custom manufacturing, you gain access to a wealth of benefits. These include:

Customization: We can customize progressive cavity pump parts to fit your specific application, ensuring optimal performance and efficiency.

Quality Assurance: Our stringent quality control measures guarantee that every component we produce adheres to strict quality standards, providing you with reliable and 2.long-lasting parts. Contact us for our Customer Testimonials.

Flexibility: We are equipped to handle various order sizes, from small-scale to large-scale production, accommodating your specific volume requirements.

Expertise: With years of experience in the industry, our team possesses extensive knowledge and technical expertise to overcome challenges and deliver solutions that exceed expectations.

Timely Delivery: We understand the significance of meeting deadlines. Therefore, we strive to deliver your customized PC pump parts within agreed-upon timelines, ensuring minimal disruption to your operations.

People Also Ask

Send Your Enquiry :