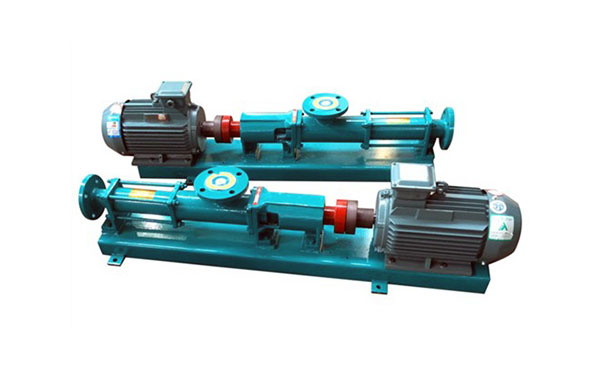

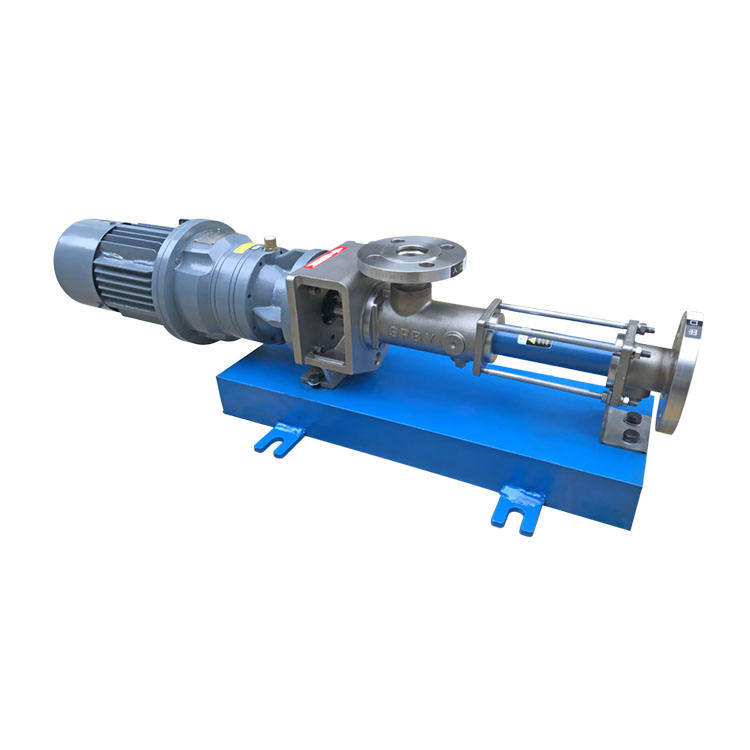

Progressing Cavity Pumps

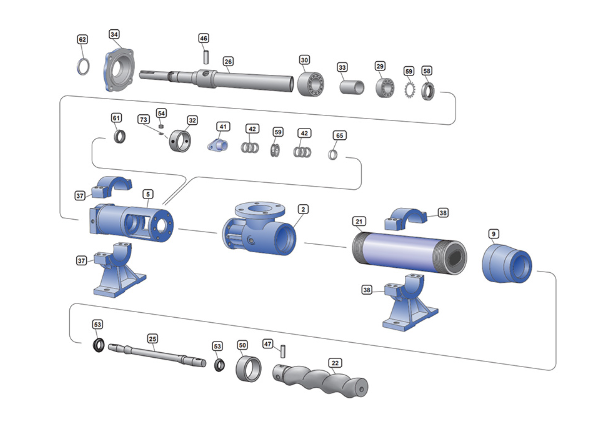

What are Progressing Cavity Pumps? Progressing cavity pumps, also known as PC pumps or screw pumps, are a type of positive displacement pump that uses a single rotating element to move fluids through a sequence of small, fixed-shape cavities. They are commonly used in various industries for fluid transfer applications due to their ability to…