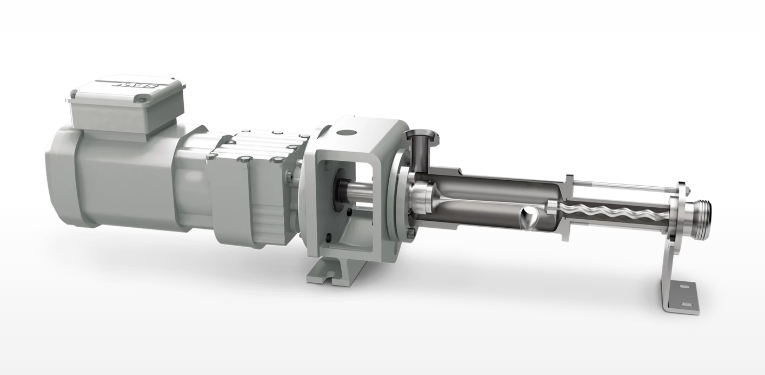

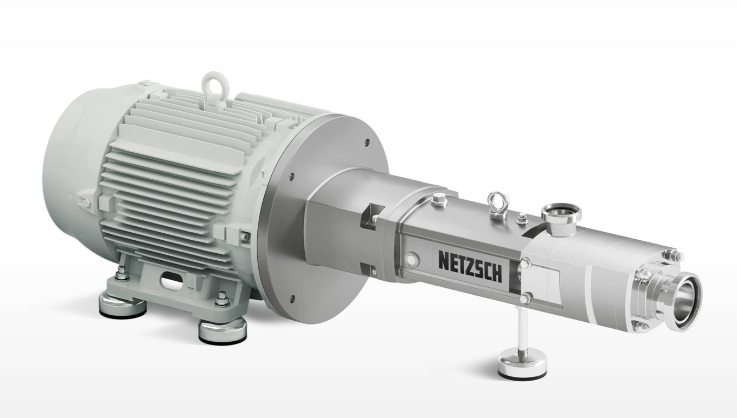

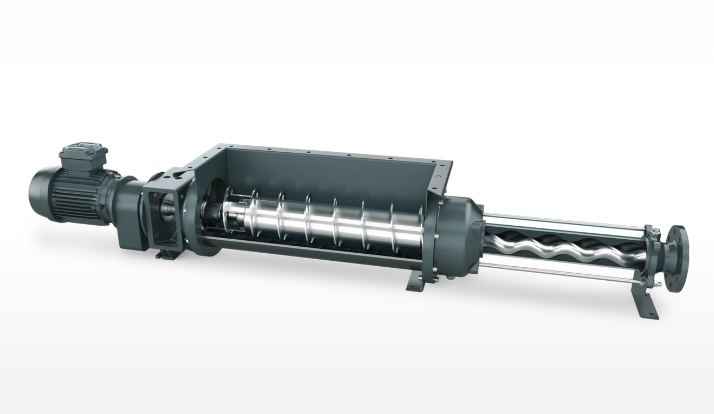

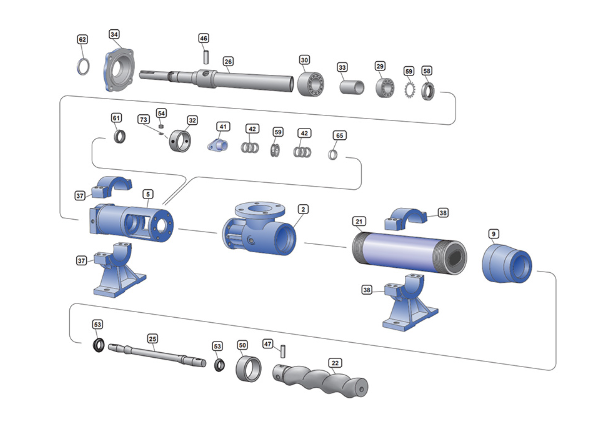

Hygienic Pump

The Description of Hygienic Pump A hygienic pump is a type of pump designed to meet the stringent requirements of sanitary processes in the food, beverage, pharmaceutical, and personal care industries. It is used to transfer high-value fluids that are sensitive to contamination, such as dairy products, beverages, cosmetics, and biopharmaceuticals. The Application of Hygienic…