Small Progressive Cavity Pump-PMV Pump

People also ask :

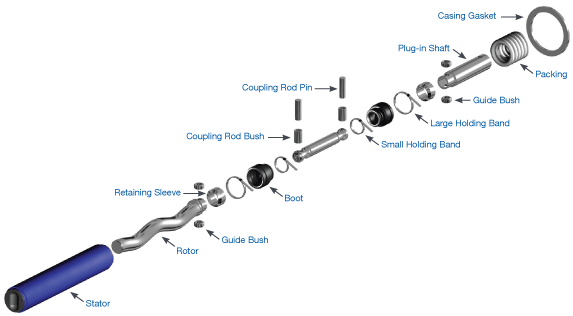

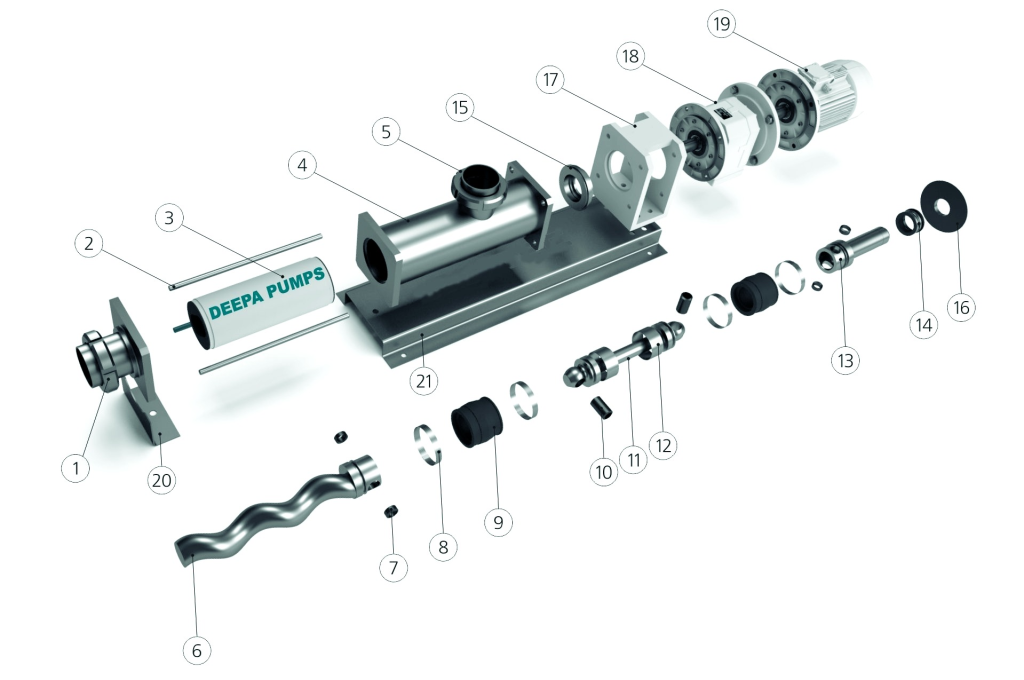

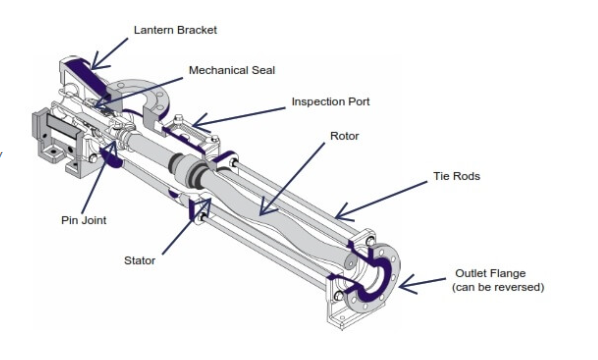

In industrial environments, various pump equipment plays a vital role. Among them, progressive cavity pumps are becoming increasingly popular due to their unique design and excellent performance. The main components of progressive cavity pumps include rotors, stators, and pump casings. The rotor is spiral-shaped, which matches the spiral shape of the stator’s inner cavity to form a unique working chamber. During the operation of the pump, these working chambers move along the rotor axis, resulting in a continuous delivery effect.

Progressive cavity pumps have many advantages, such as stable flow, wear resistance, and strong self-priming ability. This makes them widely used in many industries such as petrochemicals, food and beverages, and mining. In terms of maintenance, regular inspection and replacement of key components of progressive cavity pumps, such as rotors and stators, are essential to ensure the long-term stable operation of the equipment. Through optimized design and careful maintenance, progressive cavity pumps can provide reliable and efficient liquid delivery solutions for various industrial applications.

People also ask :

The Benefis of Seepex Range Pump

What are Progressive Cavity Pumps? Progressive cavity pumps, also known as PC pumps, progressing cavity pumps, eccentric screw pump and mono pumps are a type of rotary positive displacement pump designed for the conveying of liquids and sludges from 1cst to 1Million. They handle not only viscous fluids and solids but also gassing or multiphase…

The Description of Moyno Progressive Cavity Pumps Moyno progressive cavity pumps are renowned for their exceptional performance and reliability. These pumps are specifically designed to operate as both screw pumps and progressive cavity pumps, offering versatility in fluid handling applications. With their unique design and construction, Moyno pumps provide efficient and precise fluid transfer, ensuring…

The diverse fields of application of our rotors Artemis rotors are often used in pumps at elevated temperatures. In order to ensure that the conveying system runs efficiently and smoothly, we adjust the rotor dimensions according to the expansion that occurs. As a specialist in components for conveyor technology, our rotors are used in the…

What is Pump Stator Stators are metal tubes with internally molded cavities of synthetic or natural rubber. The rotor seals tightly against the flexible rubber inside the stator as it rotates, forming tightly sealed cavities which carry the liquid toward the discharge port.