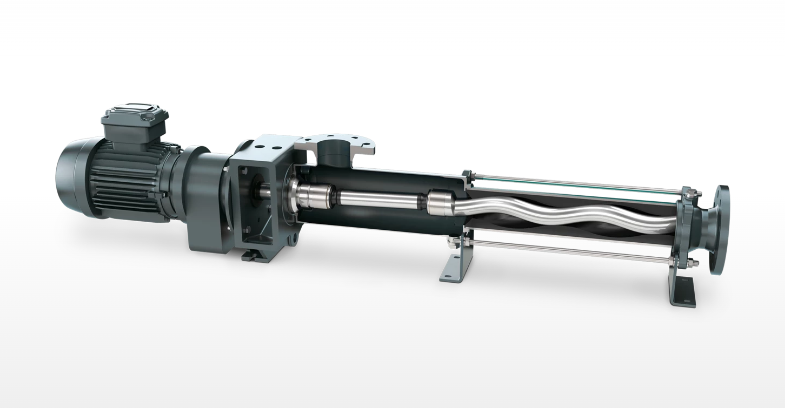

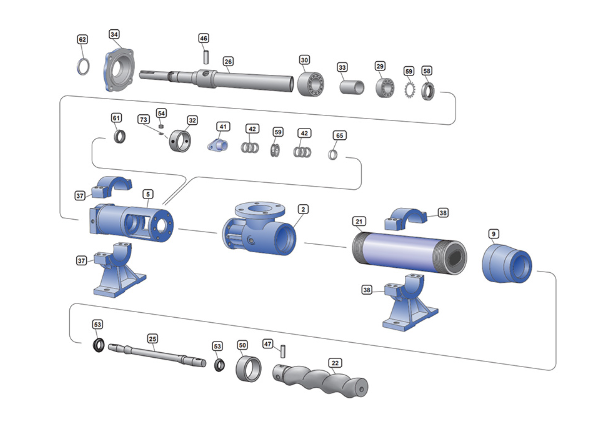

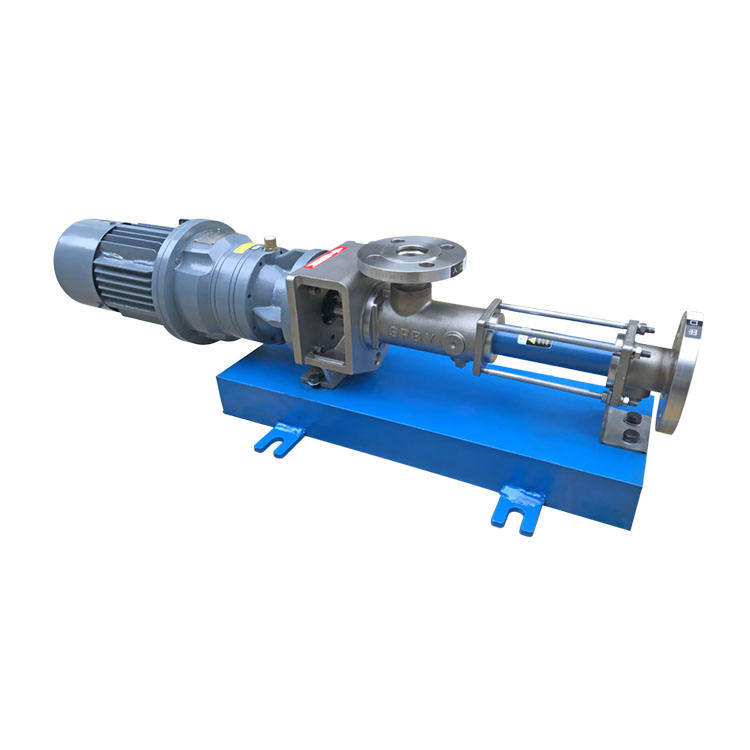

NETZSCH NEMO BY Progressing Cavity Pump in Industrial Design

NEMO BY Progressing Cavity Pump NEMO BY Progressing Cavity Pumps convey a wide array of substances or very precisely meter substances in numerous industrial applications. From low viscosity substances to products barely capable of flowing, with or without solid content, shear-sensitive, sticky or abrasive with the NEMO® BY, even difficult substances are pumped gently and with low pulsation. Pump curve PC Pump…