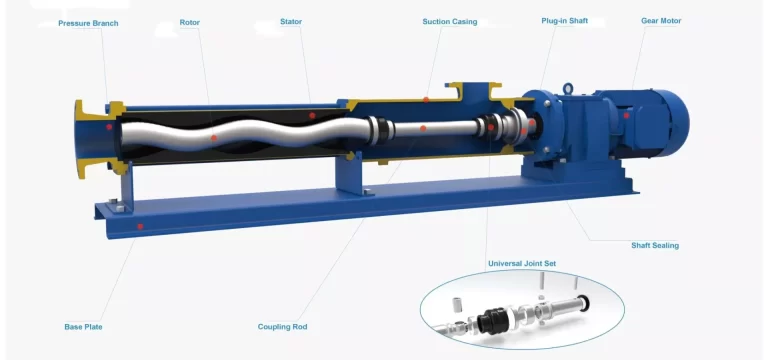

BN5-48 rotor Seepex

Features of Seepex BN5-48 Rotor First of all, the Seepex BN5-48 rotor is designed with highly wear-resistant materials and can work stably for a long time in various harsh environments. This rotor is particularly suitable for handling viscous liquids and solid particles, and is widely used in industries such as food, medicine, chemical industry and…