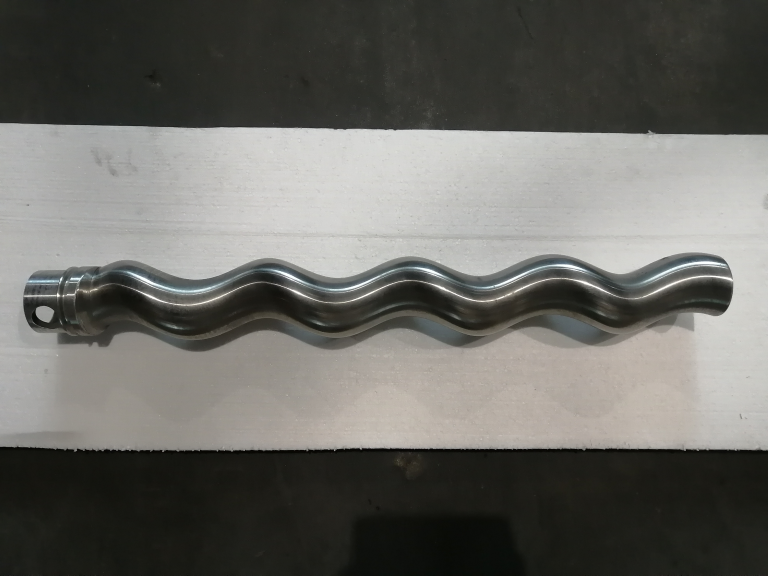

BN52-12L Connecting rod seepex

Main features of seepex BN52-12L connecting rod seepex BN52-12L connecting rod has the following main features: Typical application scenarios of seepex BN52-12L connecting rod With its excellent performance, seepex BN52-12L connecting rod is widely used in the following fields: Wastewater treatment: It is widely used in sewage treatment plants and industrial sewage treatment systems, and…