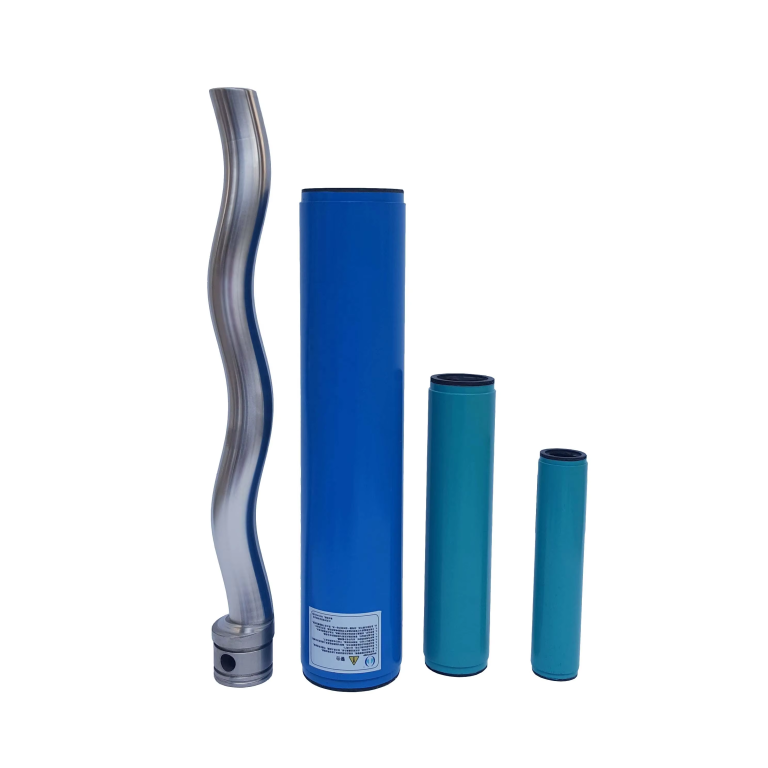

BN70-18L stator seepex

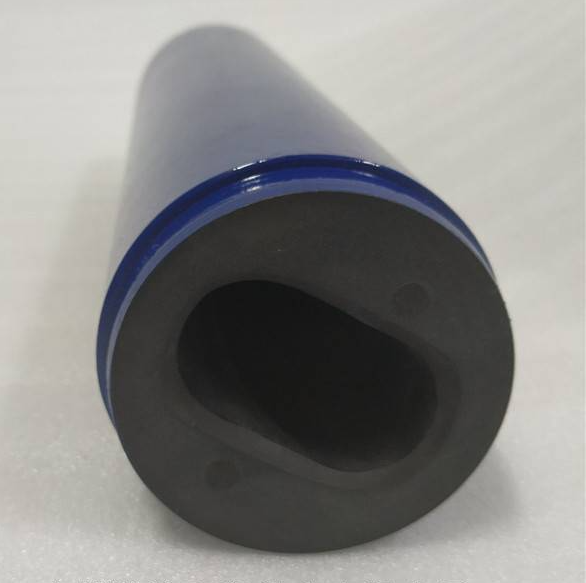

What is a stator? The stator of a screw pump is one of the core components of a screw pump. It consists of a stator core and a stator sleeve. The stator core is made of cast iron or steel plate, and has a certain rigidity and strength to support the work of the stator…