[wpseo_breadcrumb]

NEMO® C.Pro® Universal Dosing Pump

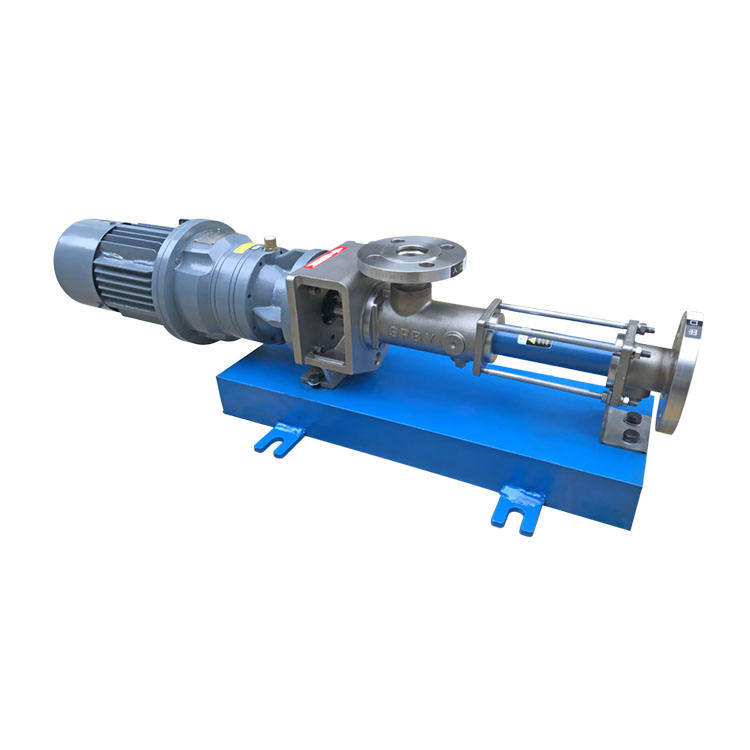

The NETZSCH NEMO® C.Pro® Universal Dosing Pump is a precision metering pump suitable for dosing a wide range of fluids. The netzsch pumps has a modular design, advanced control system, and is available in various materials for specific application requirements. It is a dependable solution for metering and dosing in various industries.

Description of the NEMO C.Pro Universal Dosing Pump

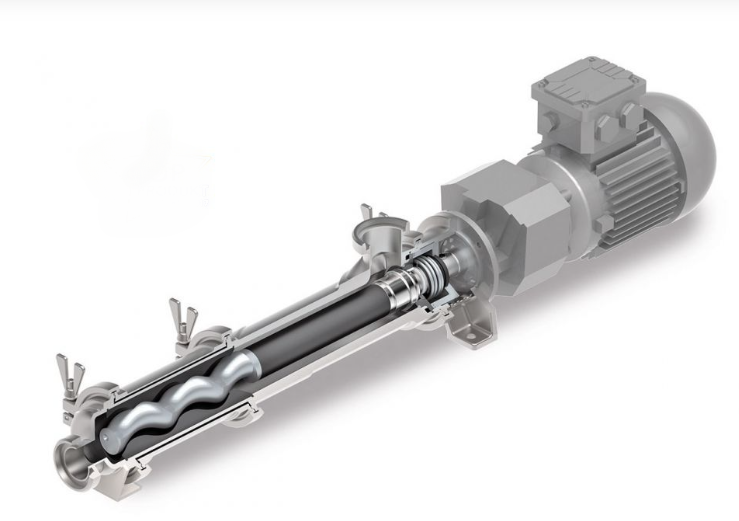

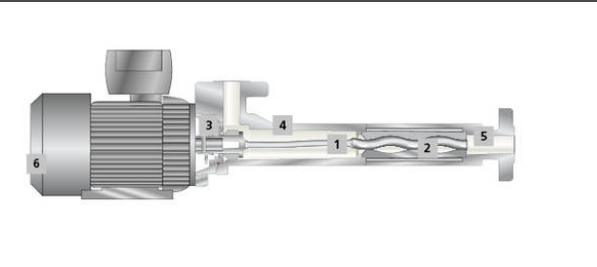

The compact synthetic pump ensures continuous conveyance that is independent of pressure and viscosity fluctuations. In addition, it enables dosing accuracy proportional to speed over the entire speed range. Its wide range of applications includes both solids-free and solids-containing, low to medium viscosity (up to 20,000 mPas), thixotropic, dilatant, shear-sensitive, abrasive, lubricating, non-lubricating, aggressive (pH 0-14) and adhesive media. With only six main parts, the NEMO® C.Pro is furthermore extremely service-friendly and economical Constant and nearly pulsation-free dosing Dosing in proportion to rotation speed Reversible direction of rotation and dosing Large dosing range Gentle product conveyance Universally applicable for many media – even acids and bases Easy serviceability

Features of the NEMO C.Pro

- universally applicable for many media – even acids and bases

- continuous low-pulsation conveyance unaffected by fluctuations in pressure and viscosity

- conveyance volume in proportion to rotation speed with high dosing precision over the entire rotational-speed range

The NEMO C.Pro offers you

- constant and nearly pulsation-free dosing

- dosing in proportion to rotation speed

- reversible direction of rotation and dosing

- large dosing range

- gentle product conveyance

- easy serviceability

Description of the NEMO® C.Pro® Universal Dosing Pump

The NETZSCH NEMO® C.Pro® Universal Dosing Pump is a highly reliable and precise pump used for the accurate dosing of various fluids in a variety of industries, including chemical, pharmaceutical, food and beverage, and wastewater treatment. It is designed to handle a wide range of viscosities and flow rates, making it an ideal choice for applications that require consistent, controlled dosing. The pump also features advanced connectivity options, enabling remote monitoring and control, as well as easy integration into existing automation systems.

| Fluid | for chemicals |

| Operation | with electric motor |

| Priming | self-priming |

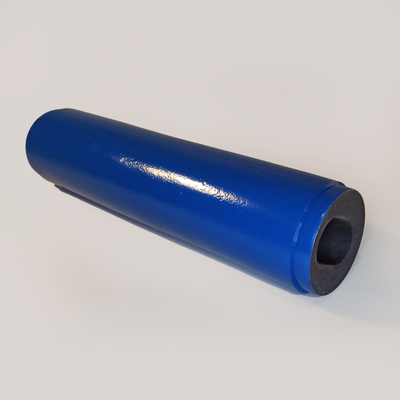

| Technology | progressive cavity |

| Mobility | stationary |

| Domain | for the chemical industry |

| Applications | metering, conveying, proportional dosage |

| Material | plastic |

| Fluid specification | for abrasive fluids, for solids-laden fluids, for low-viscosity fluids, for medium-viscosity products, for high-viscosity fluids |

| Flow | Max.: 1.5 m³/h (52.972 ft³/h) Min.: 0 m³/h (0 ft³/h) |

| Pressure | Max.: 20 bar (290.075 psi) Min.: 0 bar (0 psi) |

People Also Ask

Send Your Enquiry :