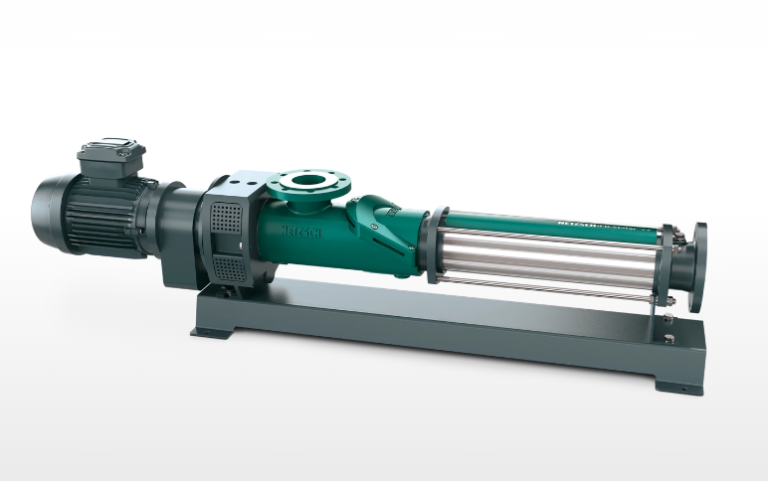

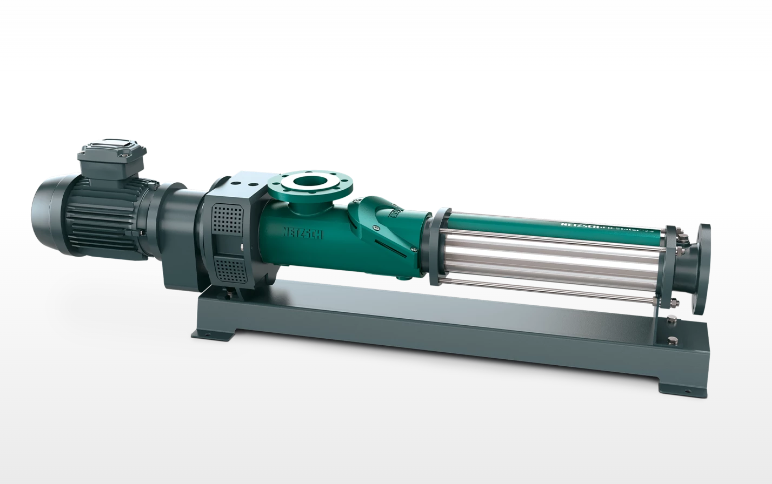

| Manufacturer | NETZSCH | Inlet flange | 100 mm |

| Type | NM063BY02S12B | Outlet flange | 100 mm |

| Flow | Max. 10 m³/h | Dimensions | Lenze 5.Approx. 2130 x 270 x 600 mm |

| Pressure | Max. 7 bar | Variable gear motor | Lenze 5.5 kW |

NETZSCH NM063BY02S12B screw pump combines the advantages of high flow, high pressure, large diameter, strong power and compact appearance. It is an outstanding industrial pump product and is widely used in various industries such as chemical, food and pharmaceutical.

Application fields

Building materials industry: Suitable for conveying building materials of various viscosities such as mortar and fillers.

Environmental protection industry: Can be used for conveying and circulating sludge, sewage, mud, etc.

Food and beverage industry: Can be used to convey foods of various viscosities and containing solid particles, such as syrup, jam, chocolate, etc.

Chemical industry: Suitable for conveying various chemicals, such as acids, alkalis, solvents, paints, coatings, etc.

Pharmaceutical industry: Can be used to convey various pharmaceutical raw materials and products, such as emulsions, suspensions, etc.

NETZSCH NM063BY02S12B screw pump has the following advantages

flow delivery capacity: The maximum flow can reach 10 m³/h, which meets the needs of large flow delivery.

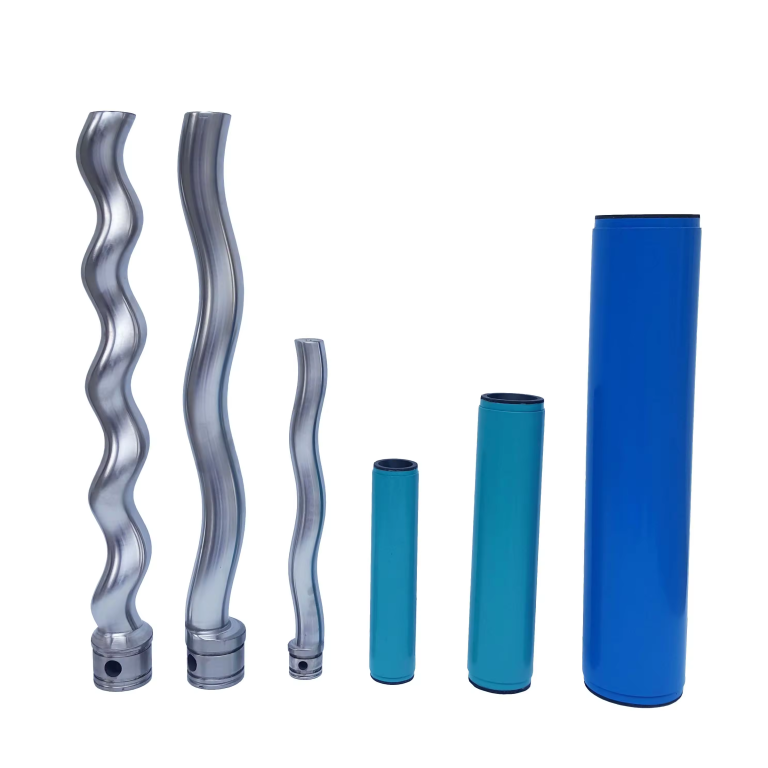

Advanced structure: The variable rotor design improves the flexibility and adaptability of fluid delivery.

High pressure delivery: The maximum working pressure can reach 7 bar, which is suitable for various high-pressure application scenarios.

Powerful: 5.5 kW variable frequency and variable speed motor provides sufficient power output for the pump.

Simple maintenance: The whole machine has a reasonable structure, and it is easy and quick to disassemble and repair.

Large-diameter flange: The inlet and outlet flange sizes of 100 mm are convenient for connection with the pipeline system and reduce pipeline resistance.

Compact size: The overall dimensions of the whole machine are about 2130 x 270 x 600 mm, which is convenient for installation and integration.

Good wear resistance: Made of high-quality wear-resistant materials, it has a long service life.

People also ask

Send Your Enquiry :