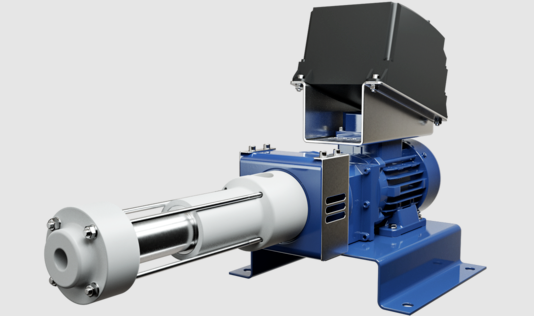

BN10-6L seepex BN

Parameters

| Brand: SEEPEX | Efficiency: 98% |

| Drive mode: Electric | Output flow: 200 |

| Performance: Wear-resistant | Weight: 60kg |

| Conveying medium: Clean water pump | Power: 2.2kW |

| Pump shaft position: Horizontal | Shaft power: 2.2 |

| Flow rate: 2.6-12 (m3/h) | Working temperature: Normal temperature |

| Lift: 60m | Application: Metering pump |

| Speed: 319 (rpm) | Material: Stainless steel |

| Suction diameter: DN65 (mm) | Model: BN10-6L |

| Discharge diameter: DN50 (mm) | Number of impellers: Single stage |

BN10-6L has the following advantages:

The core of the Seepex BN10-6L lies in its unique rotor and stator structure. The rotor is made of highly wear-resistant materials to ensure that it can maintain stability under high loads and harsh working environments. The geometric design of the rotor significantly reduces the shear force on the fluid during the conveying process. This feature is essential for many fluid treatments, especially sensitive fluids in the food and chemical industries.

The stator is made of elastic material, which can effectively improve the sealing performance of the pump and prevent leakage. This perfect match between the rotor and the stator makes the Seepex BN10-6L perform particularly well in flow and pressure output, ensuring stable fluid delivery.

The Seepex BN10-6L not only has excellent conveying capacity, but also provides flexible operating options. Users can easily adjust the speed of the pump according to specific needs to achieve different flow and pressure delivery. This flexibility allows the BN10-6L to adapt to various changing process conditions and improve overall production efficiency.

The maintenance of the BN10-6L is very simple. Due to the user-friendly design of the rotor and stator replacement process, users only need a small amount of time and effort to complete regular maintenance. This low maintenance feature reduces downtime and operating costs for industrial companies.

Send Your Enquiry :