Parameters

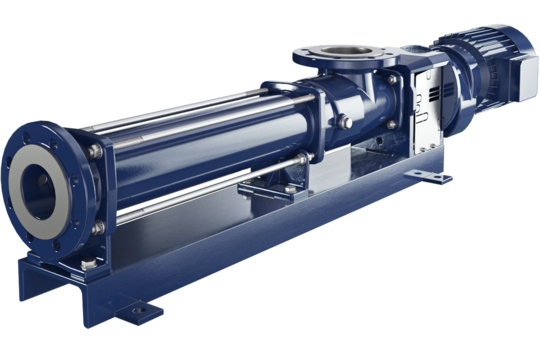

- Brand: SEEPEX

- Product features: No pulsation

- Pressure: 1.2Mpa

- Pump shaft position: Horizontal

- Impeller suction mode: Single suction

- Drive mode: Electric

- Performance: High pressure

- Transport medium: Sewage pump, impurity pump

- Scope of application: Sludge and sewage

- Flow rate: 13m3/h

- Lift: 120m

- Impeller structure: Single impeller

- Working pressure: 1.2MPa

- Weight: 145kg

- Voltage: 380V

- Application: Sewage pump

- Material: Stainless steel

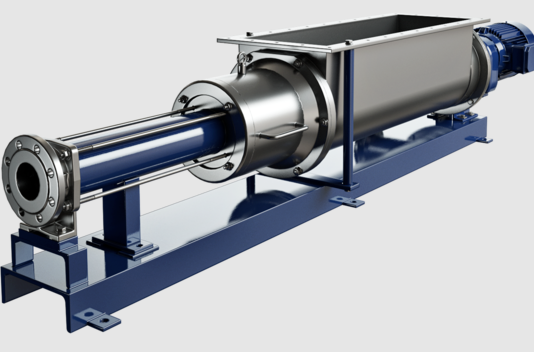

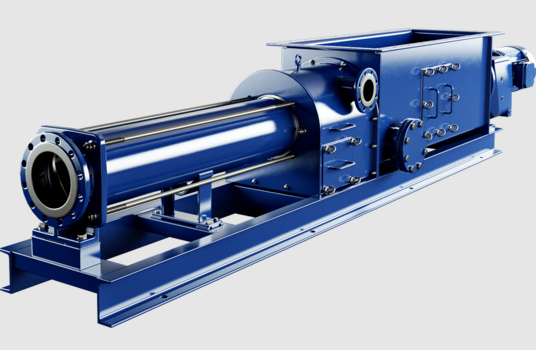

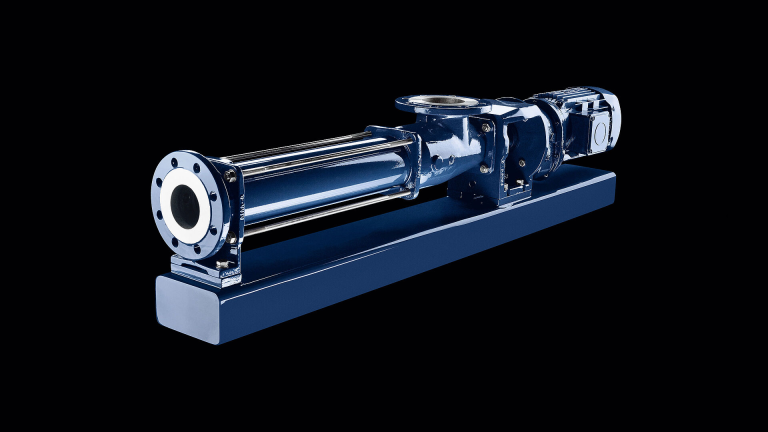

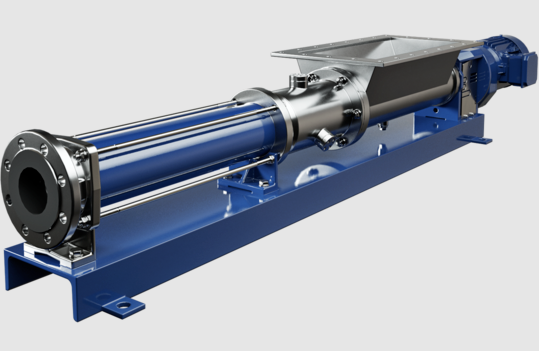

- Model: BN26-6L

Introduction

The rotor is the dynamic part of the pump, which rotates along the inner wall of the stator to create negative pressure and suck in the liquid. The stator is the stationary part, forming a sealed studio around the rotor. This design not only reduces the shear force of the liquid, but also maintains the original properties of the liquid during the conveying process, which is suitable for conveying sensitive materials such as dairy products and cosmetics.

seepex BN26-6L is widely used in food, chemical, environmental protection and other fields. Its excellent performance makes it perform well when handling viscous fluids. In the food industry, it can safely convey various liquids and meet the requirements of hygiene standards. In the chemical industry, the pump can handle a variety of corrosive and viscous liquids, providing strong support for the production process.

Although the design of the seepex BN26-6L pump focuses on durability, regular maintenance is still a necessary measure to ensure its long-term stable operation. Regularly checking the wear of the rotor and stator and replacing the worn parts in time can effectively avoid the occurrence of failures.

people also ask

Send Your Enquiry :