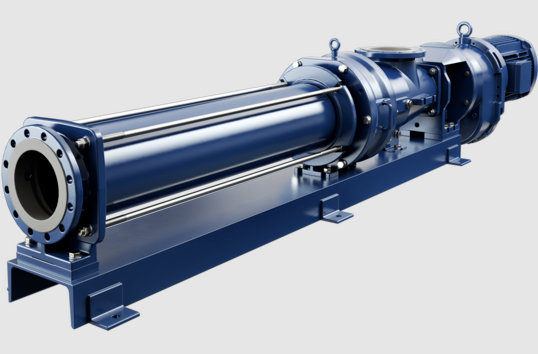

BN05-12 seepex

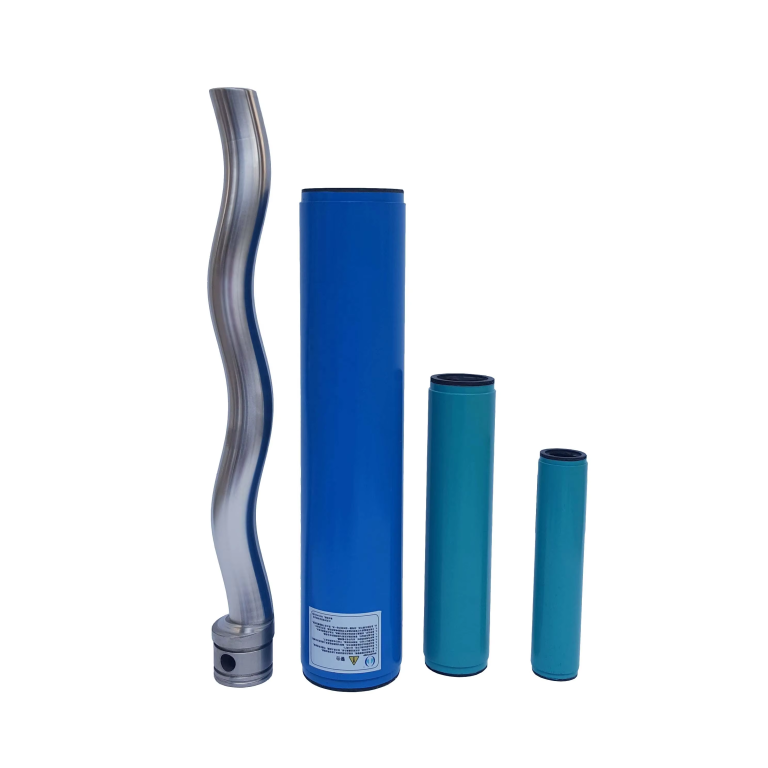

Parameters Brand: SEEPEX Suction diameter: DN10 (mm) Performance: Wear-resistant Discharge diameter: DN10 (mm) Flow rate: 0.1-0.7 (m³/h) Efficiency: 98% Drive mode: Electric Output flow: 200 Power: 0.55kW Shaft power: 0.55 Number of impellers: Single stage Working temperature: Normal temperature Pump shaft position: Horizontal Application: Metering pump Lift: 60m Material: Stainless steel Speed: 298 (rpm) Model:…