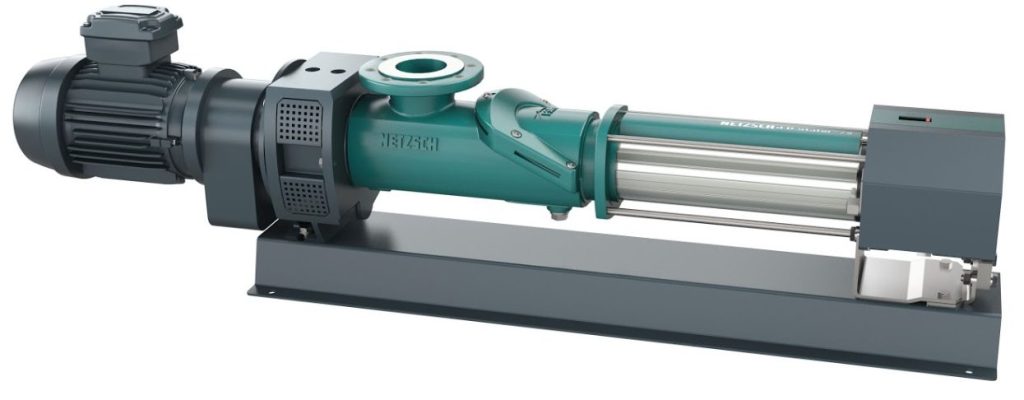

BN70-18L seepex BN

Parameters Main features of BN70-18L Excellent performance The design of BN70-18L pump fully considers the characteristics of fluids and can deliver various viscous substances at a stable flow rate and pressure. Whether it is a high-viscosity liquid or a mixed liquid, the pump can maintain excellent efficiency. Structural design BN70-18L pump adopts an advanced screw…