BN100-12L seepex BN

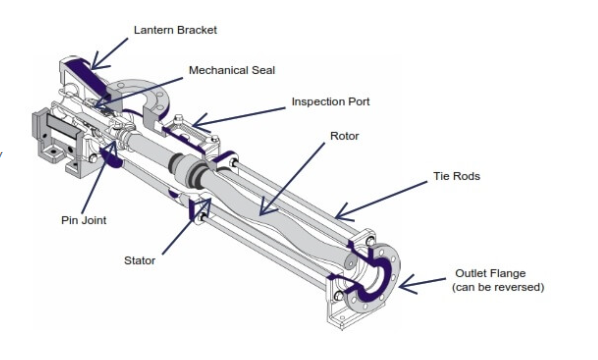

Parameters Design features seepex BN100-12L adopts a unique design concept, making full use of the structural characteristics of the screw pump, while ensuring stability and durability, taking into account flexibility and versatility. Its unique BN100-12L rotor and BN100-12L stator structure can ensure stable and efficient delivery of liquid media of various viscosities under various working…