A progressive cavity pump typically has screws quizlet

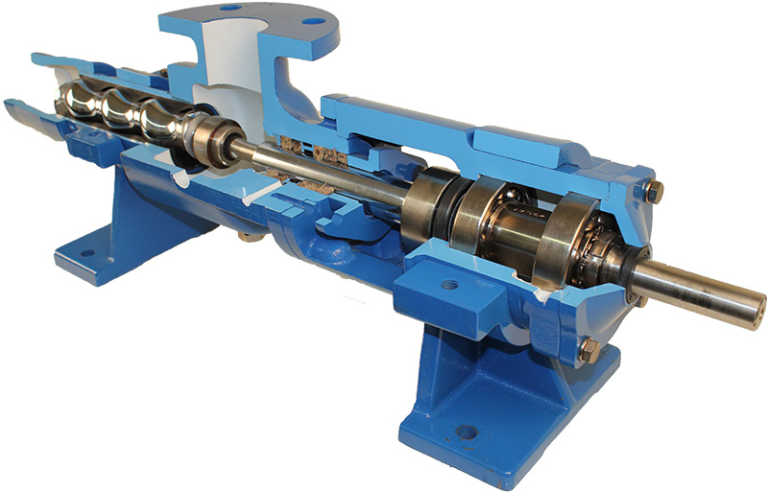

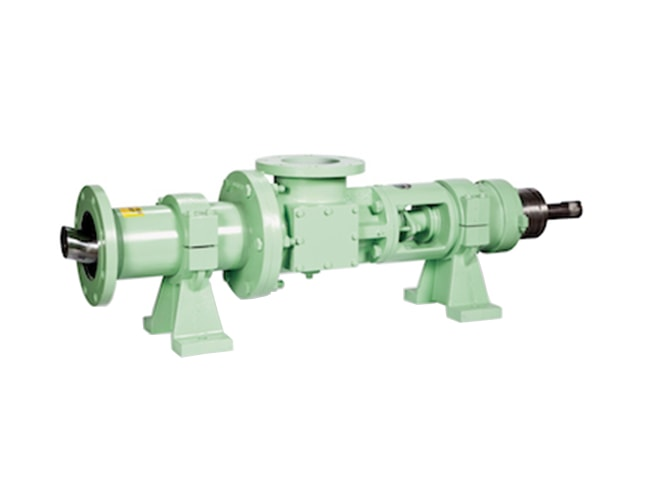

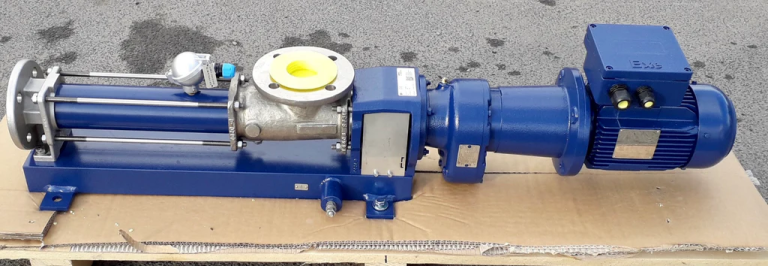

In the industrial and engineering sectors, progressive cavity pumps are widely recognized for their unique operating principles and broad applications. This article will explore the structure, working mechanism, advantages and disadvantages, and applications of progressive cavity pumps. Basic Structure of a Progressive Cavity Pump A progressive cavity pump mainly consists of the following components: Working…