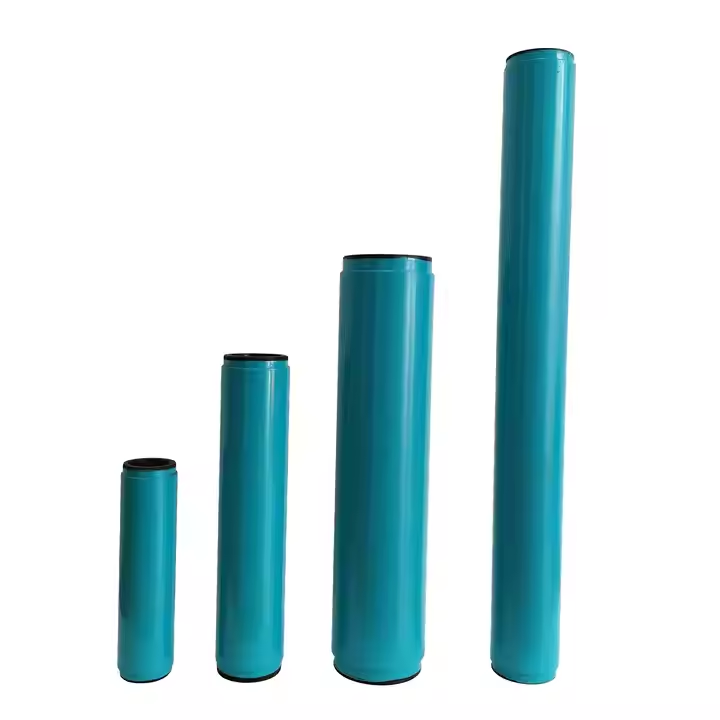

BN52-6L rotor seepex

Working principle The working principle of the seepex BN52-6L rotor is based on the basic mechanism of a screw pump. When the rotor rotates in the pump body, it forms a continuous spray chamber. This design not only reduces resistance to fluid flow, but also ensures uniform flow and pressure output. The tight fit between…