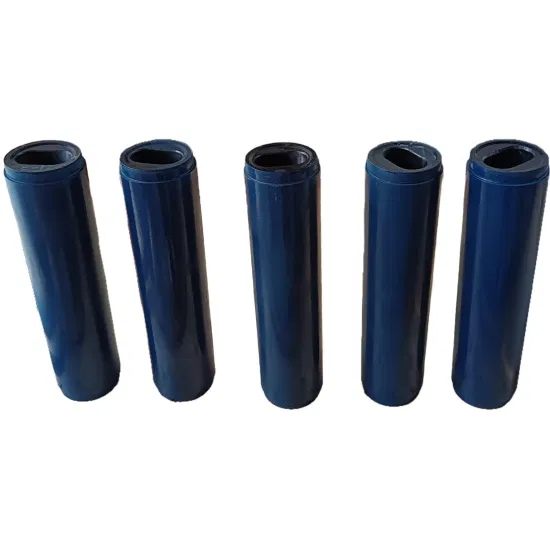

BN52-6L stator seepex

Design Features The seepex BN52-6L stator is made of high-quality materials and is designed to provide excellent wear and corrosion resistance. The design of this stator usually includes an efficient screw conveying system that can effectively handle a variety of viscous fluids. Its compact structure makes it easy to install in environments with limited space,…