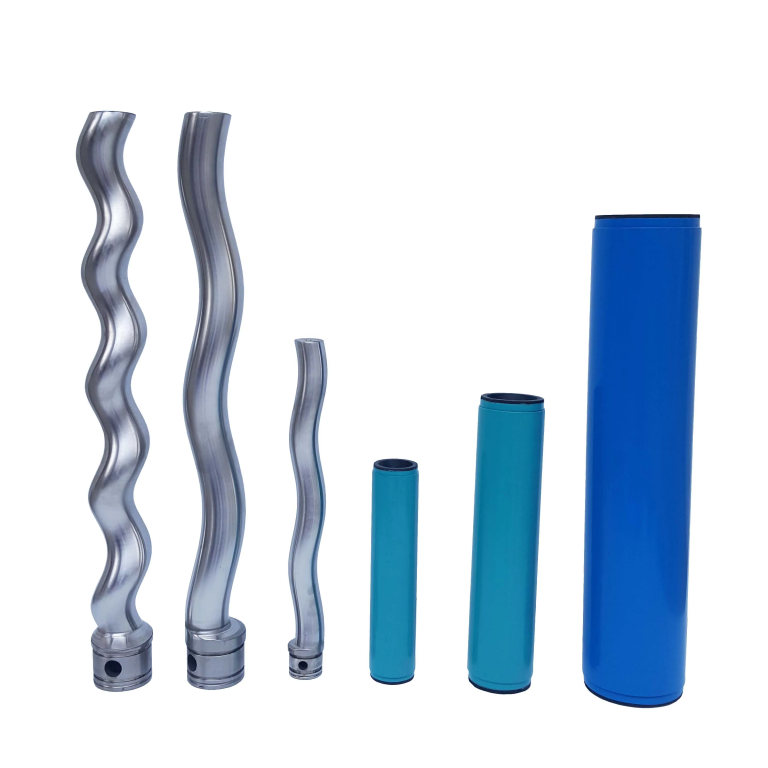

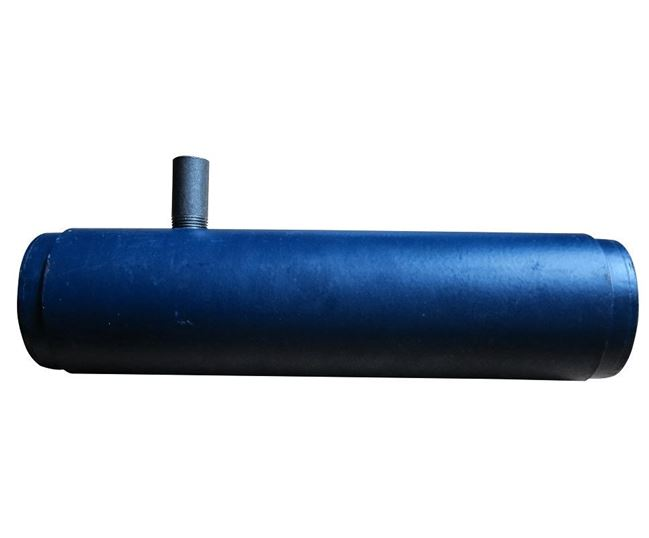

BN35-12 rotor seepex

Introduction Performance The seepex BN35-12 rotor can achieve gentle and uniform conveying, avoiding excessive shearing and damage to the medium. This not only ensures the stability of product quality, but also greatly improves the service life of the pump. Compared with traditional single-screw pumps, the BN35-12 rotor has significant advantages in conveying capacity and efficiency,…