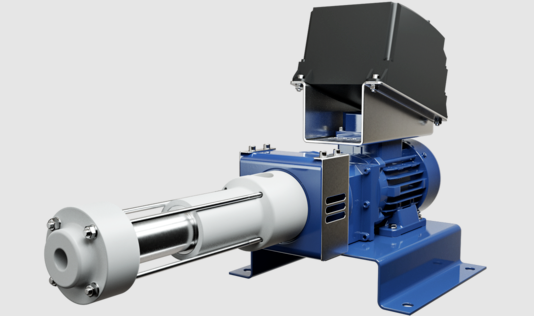

BN52-6L rotor seepex

Working principle

The working principle of the seepex BN52-6L rotor is based on the basic mechanism of a screw pump. When the rotor rotates in the pump body, it forms a continuous spray chamber. This design not only reduces resistance to fluid flow, but also ensures uniform flow and pressure output. The tight fit between the rotor and the stator further improves pumping efficiency and ensures stable fluid delivery.

Advantage analysis

Pump systems using seepex BN52-6L rotor have several significant advantages over traditional pumps:

- Efficiency: The unique design of the rotor optimizes the fluid delivery process, improves energy efficiency, and reduces energy consumption.

- Durability: Due to the use of high-quality materials, the BN52-6L rotor has excellent wear resistance, effectively extending the service life of the pump.

- Low maintenance cost: Its design reduces the failure rate of the pump and reduces maintenance costs. Enterprises can reduce downtime and improve production efficiency.

- Flexibility: The rotor can support a variety of fluid viscosities and properties, making its application range wider.

Application areas

BN52-6L rotor is widely used in many fields, including:

Sewage treatment: In the wastewater treatment process, the BN52-6L rotor can effectively transport concentrated sludge and wastewater to ensure the efficient operation of the treatment process.

Food & Beverage: This rotor design is particularly important for the food & beverage industry, where hygiene and safety are paramount considerations.

Seepex's rotor materials comply with food grade standards, ensuring no contamination during transport.

Petrochemical industry: In the petroleum and chemical industry, the BN52-6L rotor can handle various viscous fluids, ensuring the smoothness of the production process.

Pharmaceutical industry: In pharmaceutical production, the precise design and high efficiency of the rotor ensures the uniform delivery of pharmaceutical agents, which is a vital part of the pharmaceutical process.

people also ask

Send Your Enquiry :