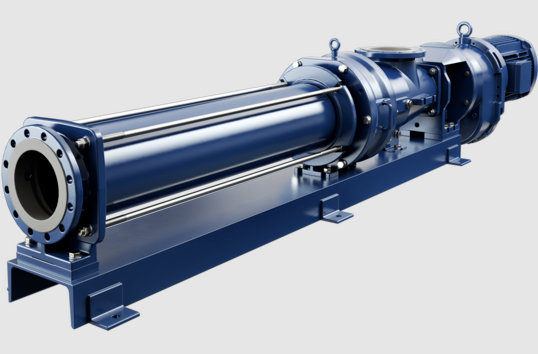

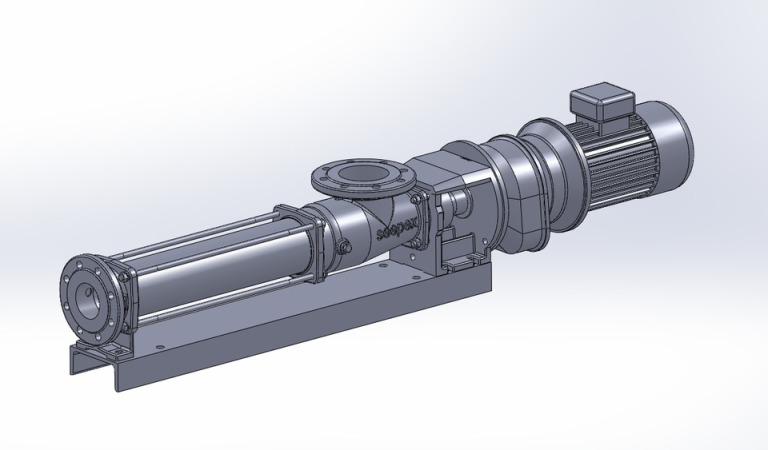

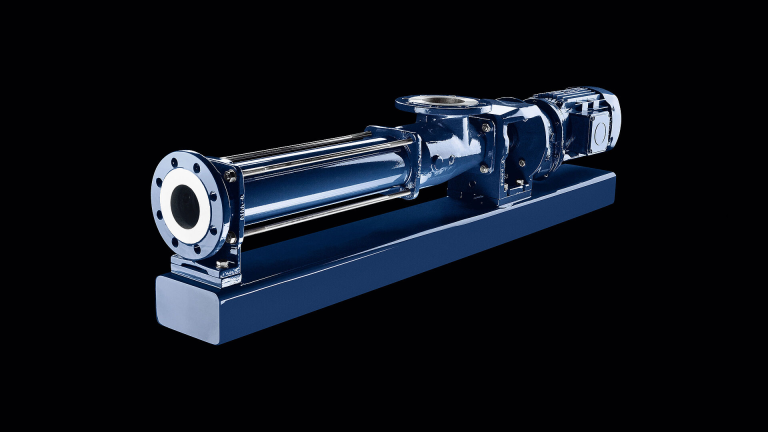

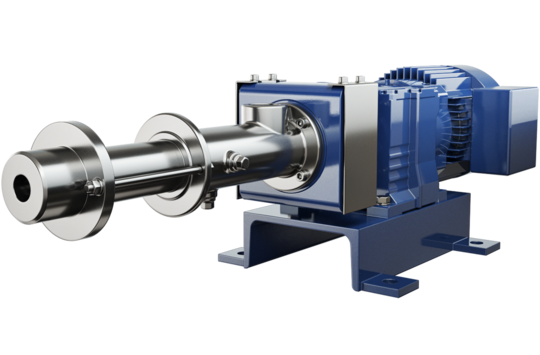

BN52-6L seepex BN

Parameters Model BN52-6L Voltage 380V Impeller structure Single impeller Conveying medium Sludge and sewage Pump shaft position Horizontal Drive mode Electric Lift 60m Flow rate 52m3/h Pressure 0.6Mpa Weight 49kg Introduction The flow rate of Seepex BN52-6L is stable and will not pulsate due to changes in the properties of the medium. At the same…