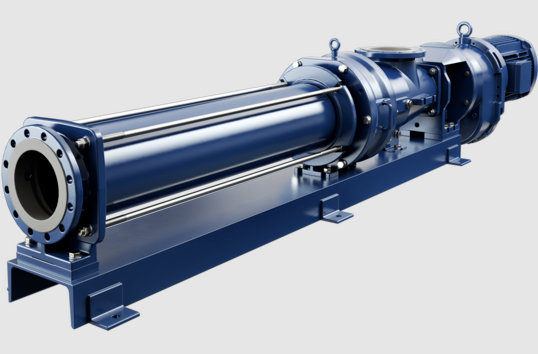

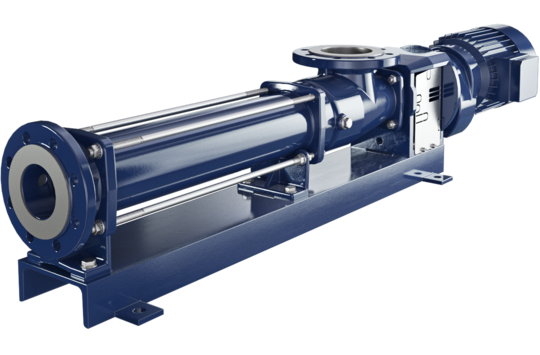

BN17-12L seepex BN

Parameters Material: stainless steel Working pressure: 1.2MPa Voltage: 380V Pump shaft position: horizontal Flow rate: 8m³/h Application scope: 60% water content Drive mode: electric Transport medium: sewage pump, impurity pump Impeller structure: single impeller Speed: 2RPM Weight: 80kg Lift: 120m Product features: 304 Impeller suction mode: single suction Application: sewage pump Performance: high pressure Brand:…