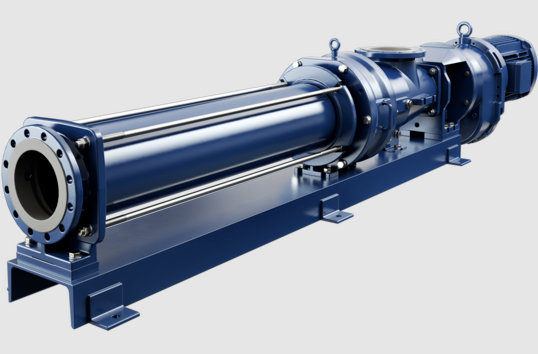

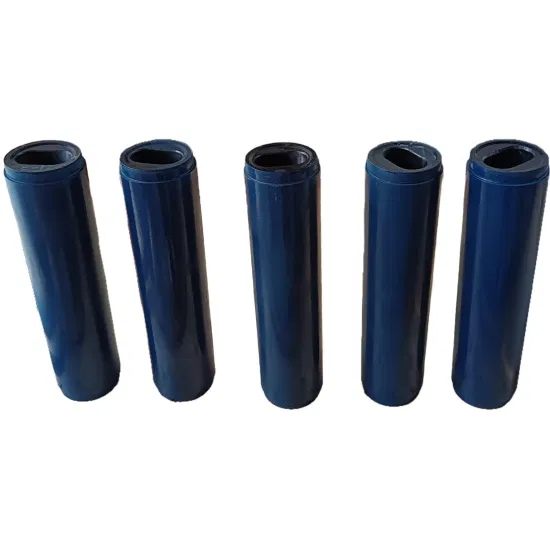

BN5-6L stator seepex

Technical Features of Seepex BN5-6L Stator The Seepex BN5-6L stator is a highly efficient screw pump component designed specifically for conveying viscous and non-viscous fluids. Its main function is to work with the rotor to push the fluid from the feed port to the discharge port. Its special geometry and material selection enable the stator…