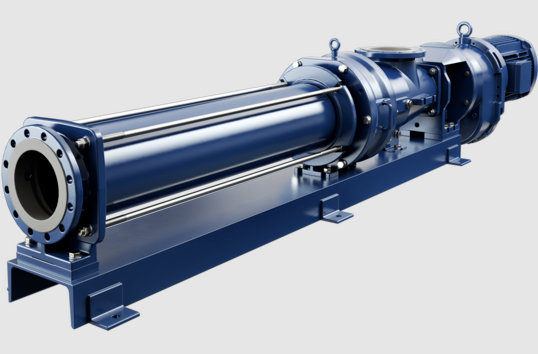

BN5-12L seepex BN

Parameters Technical features: reliable and durable The technical features of seepex BN5-12L include: Wide application areas Chemical industry: seepex BN5-12L can be used to transport various chemicals, fats, spices and other liquids. Especially suitable for fluids with high viscosity and particles. Food industry: seepex BN5-12L can be used to transport high-viscosity food raw materials such…