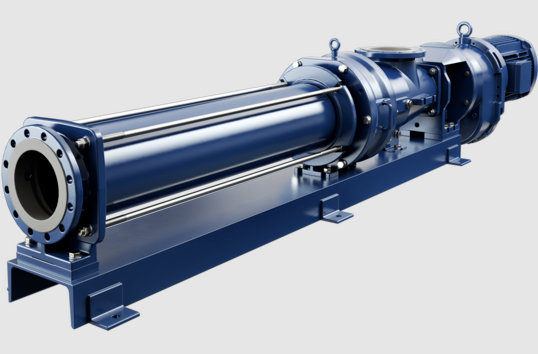

MD0005-24 stator seepex

The main function of the Seepex MD0005-24 stator is to work with the screw rotor to form a powerful closed conveying space. This structure can effectively handle various viscous and non-flowing fluids, ensuring the smoothness and continuity of the fluid during the conveying process. Whether in the chemical, food, or pharmaceutical industries, the Seepex MD0005-24…