BN35-12 stator seepex

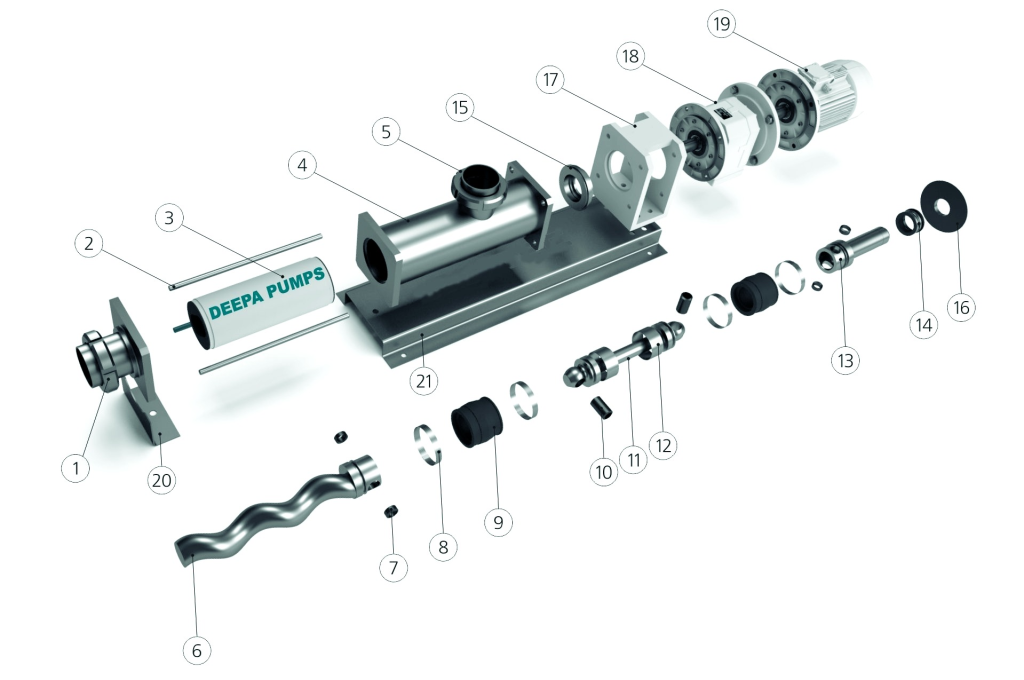

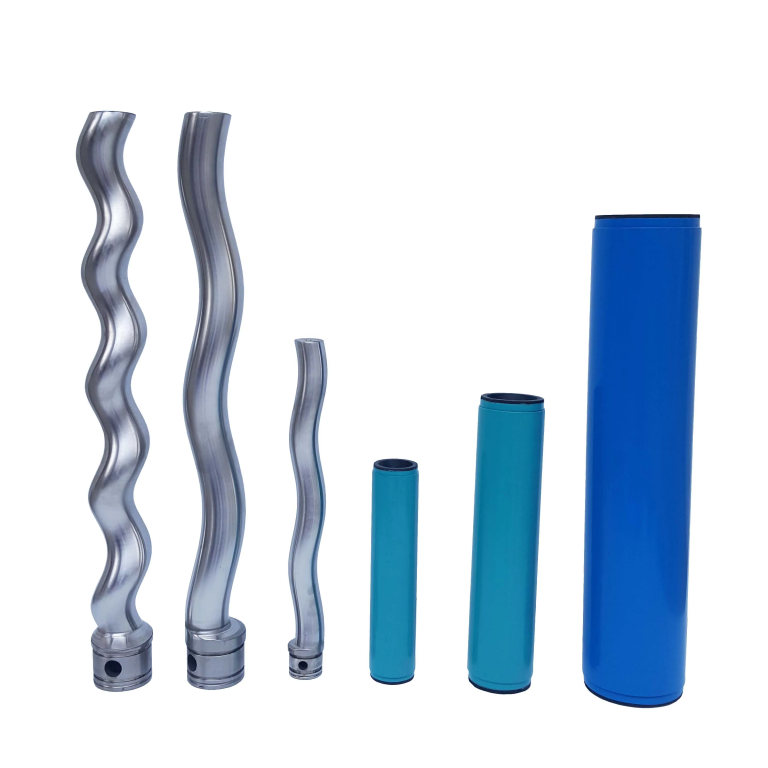

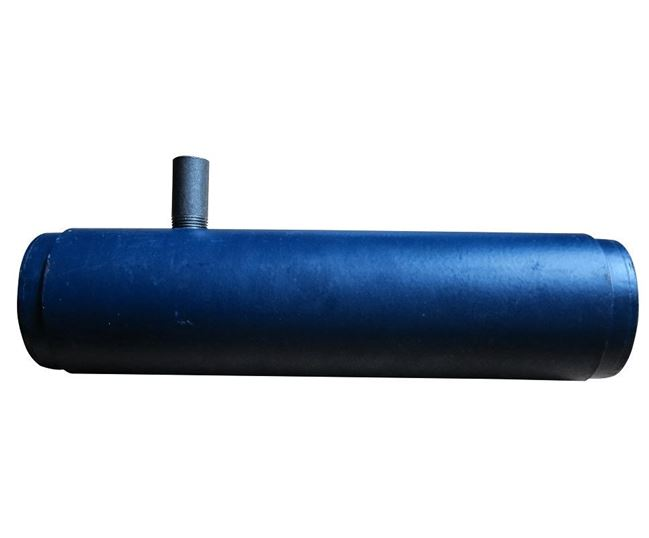

Innovative design of seepex BN35-12 Stator The seepex BN35-12 stator is an efficient screw pump component designed to meet the needs of demanding industrial applications. Made of high-quality materials, the component has excellent wear and corrosion resistance, ensuring excellent performance and reliability when handling a variety of fluids. At the same time, its unique spiral…