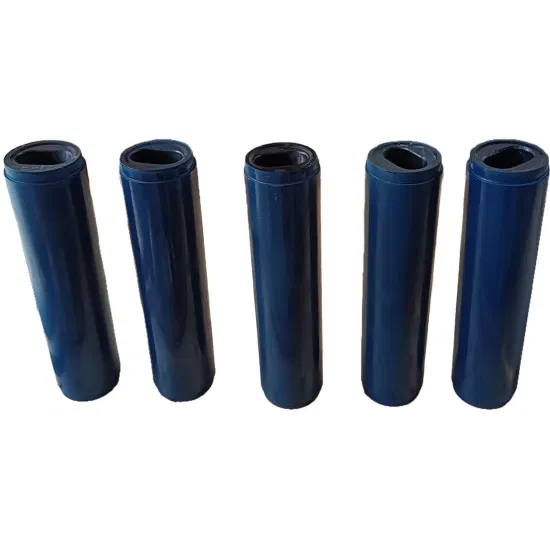

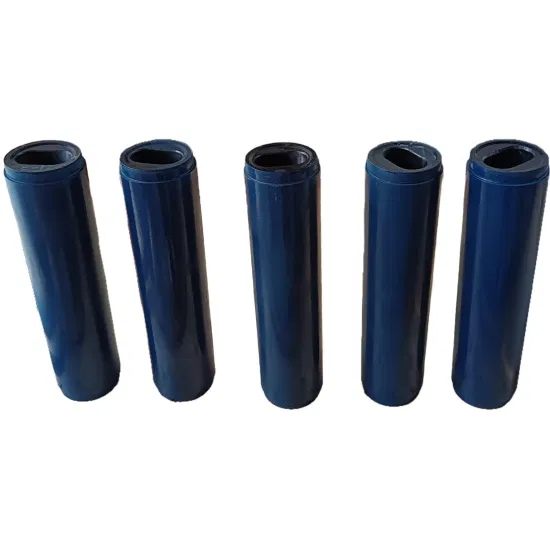

BN10-6L stator seepex

Design and Construction of BN10-6L Stator The Seepex BN10-6L stator is one of the core components of the Seepex screw pump. Its main function is to work with the rotor to form a sealed delivery chamber. The BN10-6L stator is made of high-strength polyurethane material, which has excellent wear resistance and corrosion resistance and can…