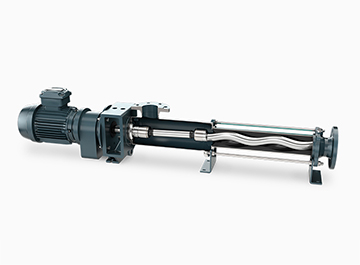

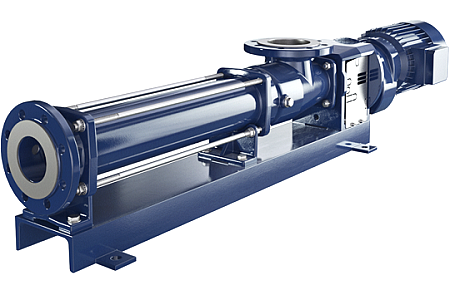

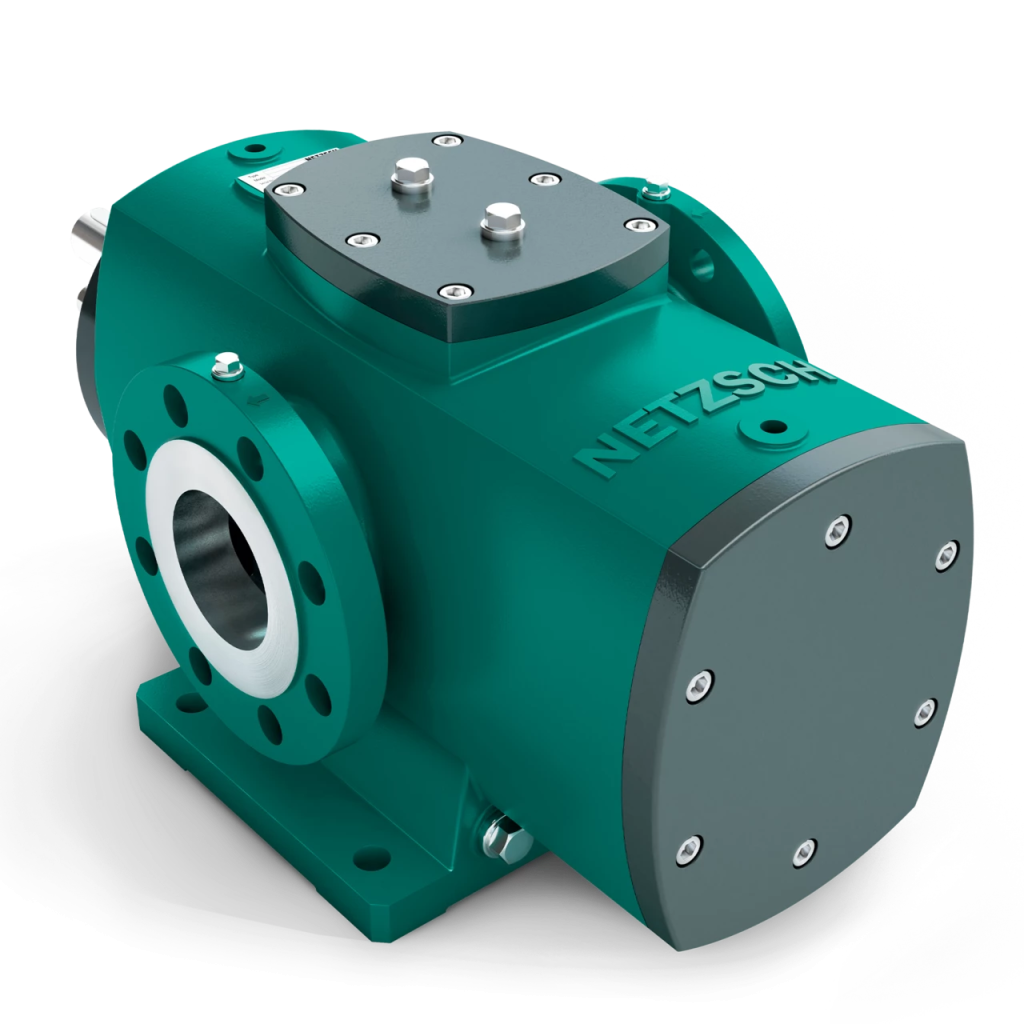

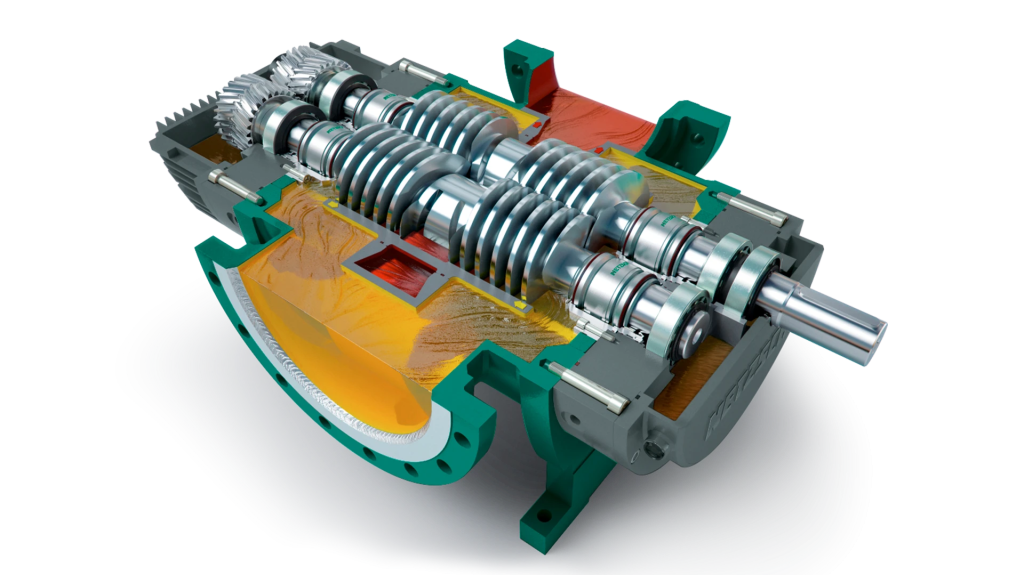

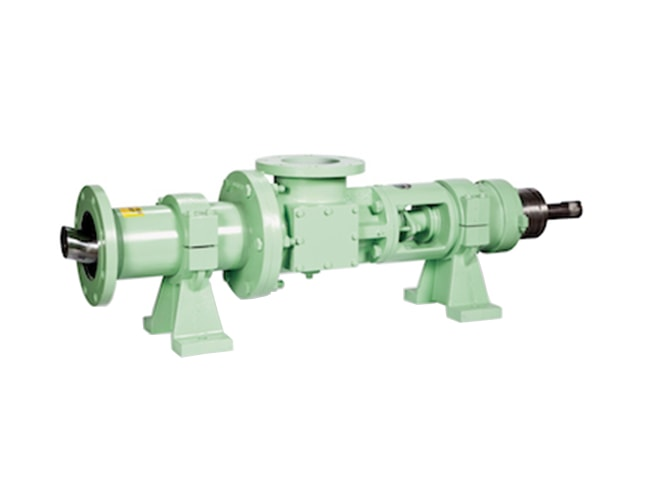

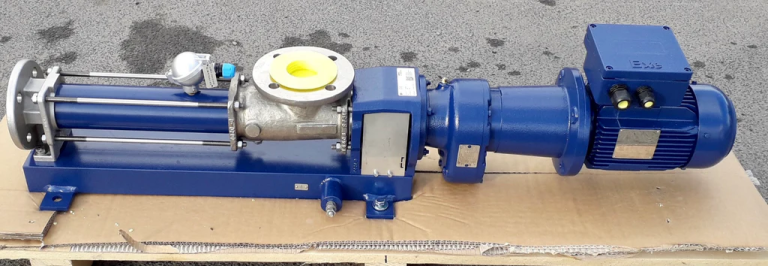

Allweiler Progressive Cavity Pump Manual

Introduction The Allweiler progressive cavity pump is renowned for its exceptional performance and reliability, making it a staple in various industrial applications. This pump design allows it to handle a wide range of fluids, including viscous liquids and those containing solid particles. This article will provide an overview of the Allweiler progressive cavity pump, including…