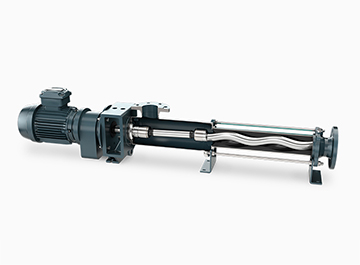

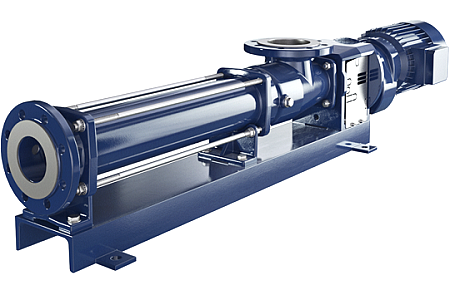

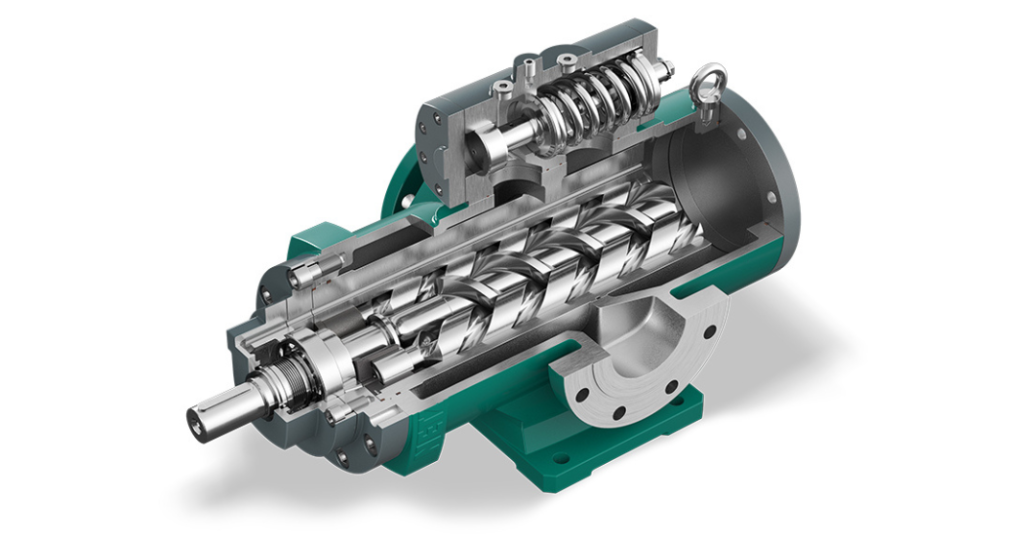

BN75-6L seepex BN

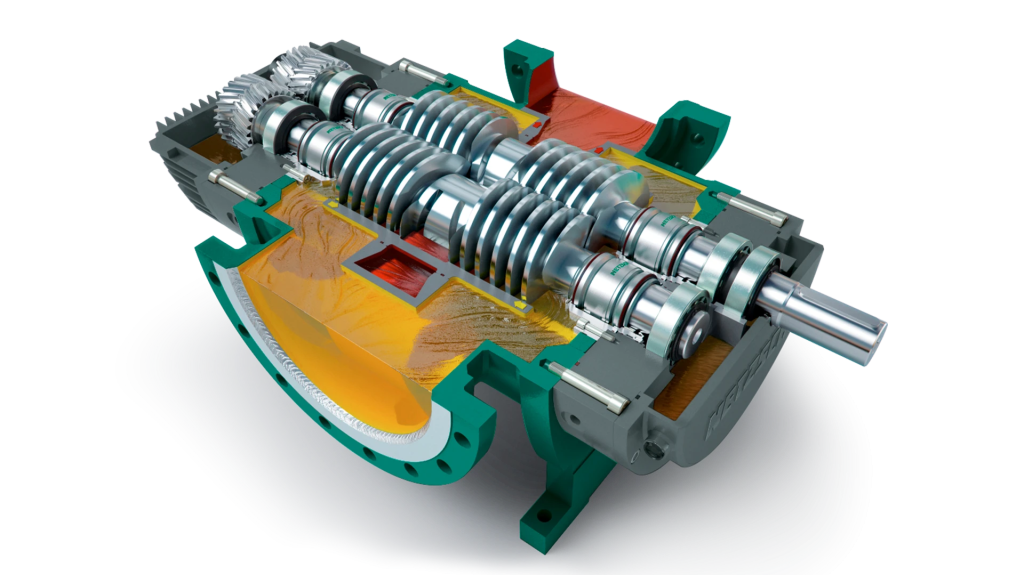

What is Seepex BN75-6L? Seepex BN75-6L is a technologically advanced screw pump designed for conveying viscous fluids and media containing solid particles. The pump uses the principle of a screw pump to push the fluid to the discharge end through a rotating screw. It has a simple structure and is easy to maintain, making it…